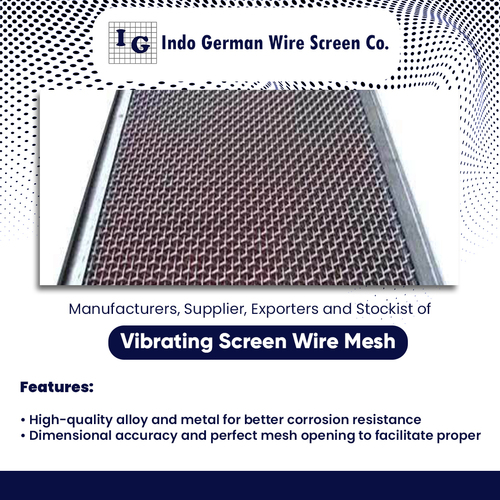

Vibrating Screen Wire Mesh for Sieving

Price 50 INR/ Unit

Vibrating Screen Wire Mesh for Sieving Specification

- Wire Gauge

- 8-24 SWG

- Aperture

- 0.5 mm to 100 mm

- Surface Treatment

- Coated

- Length

- 2 - 30 meters

- Hole Shape

- Rectangular or Square

- Product Type

- Wire Mesh

- Mesh Type

- Welded or Woven

- Mesh Style

- Other

- Material

- Metal Alloys

- Alloy

- Stainless steel, mild steel, or other alloys

- Application

- Other

- Dimensions

- Custom sizes available

- Wire Diameter

- 0.5 mm - 6 mm

- Weight

- Dependent on size and wire gauge

- Color

- Silver

Vibrating Screen Wire Mesh for Sieving Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Vibrating Screen Wire Mesh for Sieving

Vibrating Screens are also known as industrial vibrating screens, wire cloth is widely used for sieving .Vibrating screens products are widely applicable in different industries for their various sieving applications and come in different sizes and dimensions as well as based on customized needs of our customers. The Vibrating Screens are manufactured using high-grade materials in accordance with industry standards .Our Vibrating Screens are available in a range of sizes from 8 x 4 (2.4 m x 1.2 m) to 8 x 24 (2.4 m x 7.3 m).Vibrating Screen Wire Mesh for Sievingis available in different sizes and wide-range can be customized to fit your exact specifications in order to meet your specific application requirements. We offer an exclusive range ofVibrating Screen Wire Mesh for Sievingat unmatched quality and market leading prices.

High Performance in Demanding Environments

Made from stainless steel, mild steel, and other metal alloys, our vibrating screen wire mesh resists corrosion, handles temperatures up to 800C, and provides optimum strength for challenging wet or dry sieving. Available with various protective coatings, it ensures longevity even under constant vibration and heavy-duty use.

Customizable Specifications for Every Application

Select from a wide range of hole shapes, sizes, and wire diameters (0.5 mm 6 mm), with opening tolerances as tight as 0.01 mm. Mesh options include welded or woven types in a variety of finishesgalvanized, PVC coated, or plainwith edge types, panel lengths, and widths tailored to your requirements.

FAQs of Vibrating Screen Wire Mesh for Sieving:

Q: How is the vibrating screen wire mesh used in industrial applications?

A: The mesh is primarily used for sieving, filtration, and screening in industries like quarrying, mining, construction, and material processing. Its robust build handles the separation of different materials efficiently under both wet and dry conditions.Q: What are the available edge types, and when should each be chosen?

A: Edge types include plain, cut, and selvage. Plain edges suit general applications, cut edges are ideal for precise fitting, while selvage edges offer reinforced strength for operations with high vibration or load.Q: Where can the vibrating screen wire mesh be installed?

A: The mesh can be installed in processing plants, construction sites, quarries, mining fields, and any environment requiring effective particle separation, screening, or filtration. Custom sizing allows seamless integration into existing systems.Q: How does the mesh offer corrosion and temperature resistance?

A: It is manufactured from high-quality metal alloys such as stainless steel and is available with galvanized or PVC coatings, making it highly resistant to rust, chemicals, and exposure to temperatures up to 800C.Q: What is the process for customizing mesh dimensions and specifications?

A: Customers can specify aperture size (0.5 to 100 mm), wire diameter (0.5 mm 6 mm), length (2-30 meters), hole shape, panel type, and surface finish. The manufacturer adapts production accordingly to meet these requirements.Q: What benefits does the mesh offer compared to standard screens?

A: Owing to high tensile strength, fine tolerance, and versatile finishing, this mesh provides extended lifespan, reduced maintenance, and superior screening efficiency in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibrating Screen Wire Mesh Category

Vibrating Screen Wire Mesh for Minerals

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Other

Product Type : Wire Mesh

Material : Metal Alloys

Application : Other

Vibrating Screen for Separation

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Plain Mesh

Product Type : Wire Mesh

Material : Metal Alloys

Application : Other

Vibrating Screen Wire Mesh for Coal Industry

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Other

Product Type : Wire Mesh

Material : Metal Alloys

Application : Other, Screening and grading coal in mining industry

Vibrating Screen Wire Mesh for Steel Industry

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Other

Product Type : Wire Mesh

Material : Metal Alloys

Application : Other

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry