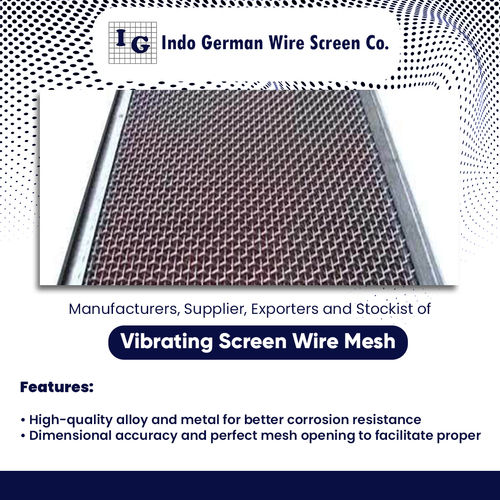

Vibrating Screen Wire Mesh for Cement Industry

Price 50 INR/ Unit

Vibrating Screen Wire Mesh for Cement Industry Specification

- Hole Shape

- Square

- Wire Gauge

- 14 Gauge to 18 Gauge

- Length

- 1 Meter to 30 Meters (customizable)

- Surface Treatment

- Coated

- Aperture

- 5mm to 100mm

- Product Type

- Wire Mesh

- Mesh Type

- Vibrating Screen Mesh

- Mesh Style

- Plain Mesh

- Material

- Metal Alloys

- Alloy

- Carbon Steel, Stainless Steel, or as specified

- Application

- Other

- Dimensions

- Available in multiple sizes or as per order

- Wire Diameter

- 1.5 mm to 3 mm

- Weight

- Varies as per size and gauge

- Color

- Silver

- Operating Temperature

- Up to 400°C

- Tensile Strength

- High Tensile

- Packing Type

- Roll or Sheet

- Finish Type

- Galvanized or custom finish available

- Corrosion Resistance

- Enhanced due to coating

- Usage

- Suitable for screening, sizing, and filtration in cement industry

- Installation

- Easy to install and replace

- Open Area

- 35% to 70%

- Edge Type

- Welded and Folded Edge

Vibrating Screen Wire Mesh for Cement Industry Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Vibrating Screen Wire Mesh for Cement Industry

Vibrating Screensprovide a custom engineered solution for all heavy-duty applications for minerals, ores, aggregates, and more.Vibrating Screens aremade for durability to give you lengthier wear life and maximum strength steel to bear heavy loading. Our Vibrating Screens are available in a range of sizes from 8 x 4 (2.4 m x 1.2 m) to 8 x 24(2.4 m x 7.3 m).

Vibrating Screen Wire Mesh for Cement Industryis available in different sizes and wide-range can be customized to fit your exact specifications in order to meet your specific application requirements. We offer an exclusive range ofVibrating Screen Wire Mesh for Cement Industryat unmatched quality and market leading prices.

Precision Engineering for Cement Applications

Vibrating Screen Wire Mesh is designed specifically for rigorous screening, sizing, and filtration processes in the cement industry. Its high tensile strength, versatile aperture sizes, and enhanced corrosion resistance ensure reliable performance even in harsh operational environments. The mesh adapts efficiently to industrial settings requiring consistent throughput and minimal maintenance.

Customizable Options for Every Project

Choose from welded or folded edges, plain mesh style, and a broad selection of materials including stainless steel and carbon steel alloys. Meshes are available in multiple dimensionsranging in length from 1 to 30 metersand can be supplied in rolls or sheets. Custom finishes and aperture sizes offer further flexibility to meet unique project requirements.

FAQs of Vibrating Screen Wire Mesh for Cement Industry:

Q: How do I install and replace the Vibrating Screen Wire Mesh in cement machinery?

A: Installation is straightforward as the mesh comes in roll or sheet formats with welded or folded edges. The design facilitates easy fitting and replacement without specialized tools, minimizing downtime in cement screening processes.Q: What are the benefits of using this wire mesh for cement industry screening?

A: The mesh offers high tensile strength for durability, advanced coatings for enhanced corrosion resistance, and customizable sizes and finishes. These features ensure precise filtration, extended service life, and reliable operation in demanding cement industry environments.Q: When should I opt for galvanized or custom-coated finishes on the mesh?

A: Galvanized finishes are ideal for environments prone to moisture or aggressive chemicals, enhancing corrosion resistance. Custom-coated finishes can be selected for specific operational needs, further safeguarding the mesh against extreme conditions commonly found in cement production.Q: Where can this vibrating screen mesh be utilized within the cement industry?

A: These meshes are suitable for screening, sizing, and filtration functions in various stages of cement processing, including raw material separation, clinker handling, and quality control sections across plants in India and global export markets.Q: What is the process for customizing mesh dimensions or specifications for a specific project?

A: You can specify length (from 1 meter to 30 meters), width, wire gauge (1418), aperture size (5mm100mm), and material requirement (carbon steel, stainless steel, etc.) when placing the order. Manufacturers offer tailored solutions to fit unique equipment and production needs.Q: What types of wire mesh edges are available, and how do they impact performance?

A: You can choose between welded and folded edge types. Welded edges provide enhanced structural stability and are suitable for high-vibration applications, while folded edges offer flexibility and easier handling during installation.Q: How does the open area percentage affect the performance of the mesh in cement applications?

A: Open area (35%70%) influences both throughput and filtration precision. Higher open area supports faster material flow, while lower open area enhances fine particle separation. The selection depends on your required balance between efficiency and screening accuracy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibrating Screen Wire Mesh Category

Vibrating Screen Wire Mesh for Sieving

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

Material : Metal Alloys

Vibrating Screen for Separation

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

Material : Metal Alloys

Vibrating Screen Wire Mesh for Coal Industry

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

Material : Metal Alloys

Vibrating Screen Wire Mesh for Steel Industry

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

Material : Metal Alloys

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry