Vibro Sifter Sieves

Vibro Sifter Sieves Specification

- Product Type

- Vibro Sifter Sieves

- Material

- Stainless Steel

- Metal Type

- Steel

- Color

- Sliver

Vibro Sifter Sieves Trade Information

- Minimum Order Quantity

- 5 Pieces

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- No

- Main Domestic Market

- All India

About Vibro Sifter Sieves

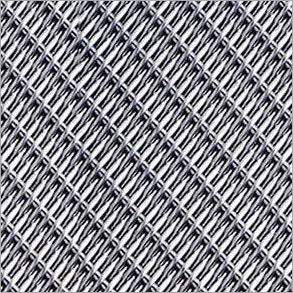

Vibro Sifter Sieves offered by us have been fabricated using superior quality SS304 alloy with galvanized surface finish. They are intended to be used for particle grading in both food & non-food industries. These sieves are highly abrasion resistant in nature and show compatibility for most anhydrous acids & alkalis. They are provided with a strong frame which holds wire mesh tightly along the edges for superior performance. Vibro Sifter Sieves are available in different mesh sizes and dimensional configurations as demanded by our clients. They are considered to be best for use under extreme working conditions.

Special Features ofVibro Sifter Sieves:

- Provided stainless steel sieves are useful for effective removal of impurities.

- Ideal for separation and filtration procedures

- Also used for sizing and grading purpose

- Corrosion proof, oxidation protected, precise mesh diameter and ease of cleaning

Product details

|

Hole Shape |

Square, Circular |

|

Material Grade |

ISO-9044, ASTM E-2016 |

|

Material |

Stainless Steel-316 and 316-L Quality |

|

Hole Size |

25.4mm to 25 microns |

Precision-Engineered for Superior Sifting

Each Vibro Sifter Sieve is constructed using stainless steel and features a polished surface to enhance product longevity and ensure easy cleaning. The steel wire mesh offers excellent resistance to corrosion and provides reliable, precise particle separation, making these sieves suitable for a wide spectrum of industrial requirements.

Trusted by Industries Across India and Globally

We proudly serve as a comprehensive manufacturer, exporter, supplier, and trader, delivering Vibro Sifter Sieves that meet stringent quality expectations. Our products are widely employed in the food, pharmaceutical, chemical, and allied industries, helping clients achieve their quality control goals efficiently.

FAQs of Vibro Sifter Sieves:

Q: How are Vibro Sifter Sieves manufactured?

A: Vibro Sifter Sieves are manufactured using premium stainless steel, shaped and welded to form durable frames, and finished with a polished surface for improved hygiene. The steel wire mesh is securely fitted to ensure consistent mesh integrity and optimal sifting performance.Q: What is the primary usage of Vibro Sifter Sieves in industry?

A: These sieves are mainly used for separating, grading, and filtering solids in various industries such as pharmaceuticals, food processing, and chemicals. Their precise mesh openings help achieve uniform particle sizes, improving product quality and process efficiency.Q: When should the Vibro Sifter Sieves be replaced or maintained?

A: The sieves should be inspected regularly for signs of mesh damage, wear, or clogging. Replacement should be considered if integrity is compromised, while routine cleaning after each use ensures optimal performance and longevity.Q: Where can Vibro Sifter Sieves be supplied from in India?

A: As leading exporters, manufacturers, suppliers, and traders, we deliver Vibro Sifter Sieves to clients across India and to international markets, ensuring reliable sourcing for businesses in need of high-quality sieving solutions.Q: What is the process of sifting using these sieves?

A: The sieving process involves placing materials into the Vibro Sifter, where vibrations drive the contents across the steel wire mesh. This motion efficiently separates particles based on size, allowing only appropriately sized materials to pass through.Q: What are the key benefits of using polished stainless steel Vibro Sifter Sieves?

A: Polished stainless steel Vibro Sifter Sieves offer high durability, corrosion resistance, easy cleaning, and maintain product purity. These features result in reduced downtime, compliance with hygiene standards, and improved process consistency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sifter Sieves Category

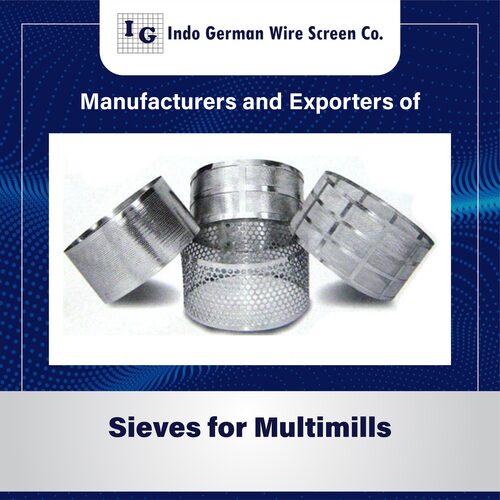

Multimill Sieves For Pharma

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet

Color : Silver

Material : Others, Stainless Steel

Product Type : Multimill Sieves

Multi Mill Sieves

Price Range 1200.00 - 5000.00 INR / Piece

Minimum Order Quantity : 5 Pieces

Color : Black

Material : Aluminum

Product Type : Multi Mill Sieves

Stainless Steel Dutch Sieves

Price Range 100.00 - 300.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Color : Silver

Material : Stainless Steel

Product Type : Stainless Steel Dutch Sieves

Flex Sifters Sieves

Price 50 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Color : silver

Material : Stainless Steel

Product Type : Flex Sifters Sieves

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry