410 Stainless Steel Perforated Sheets

Price 50 INR/ Unit

410 Stainless Steel Perforated Sheets Specification

- Surface Treatment

- Powder Coated

- Usage

- Industrial

- Material

- Stainless Steel

- Size

- Standard

- Product Type

- 410 Stainless Steel Perforated Sheets

- Color

- Silver

410 Stainless Steel Perforated Sheets Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About 410 Stainless Steel Perforated Sheets

Stainless Steel 410 Grade is a general-purpose martensitic stainless steel containing 11.5% chromium and is heat-treated to achieve optimal hardness and maximum corrosion and heat resistance. Stainless Steel 410 Grade is durable and greatly resistant to wear but is more susceptible to chemical corrosion and oxidation.Stainless Steelhas properties like easy formability, manufacturability, corrosion resistant, fire and heat resistance.Stainless Steelhas high tensile strength, temperature resistance, impact resistance, and excellent strength-to-weight ratio.The410 Stainless Steel Perforated Sheetsare the most popular perforated sheet pattern used in the current times since they are highly versatile in use, economical in cost, and have a strong aesthetic appeal. Theperforated sunshades and claddingsprovides privacy for the building residents without any view obstruction while controlling interior climate thus reducing the load of air conditioning and saving energy to a large extent.We offer an exclusive range of410 Stainless Steel Perforated Sheetsat unmatched quality and market leading prices.

Quality Construction for Industrial Needs

Our 410 Stainless Steel Perforated Sheets are meticulously crafted to meet strict industry standards. The use of high-quality stainless steel ensures a long service life, while the powder-coated surface treatment adds an extra layer of protection against corrosion and wear. This makes them ideal for demanding industrial environments.

Versatile Applications and Custom Solutions

Designed with versatility in mind, these perforated sheets are suitable for filtration, screening, architectural applications, and more. As a leading exporter, manufacturer, supplier, and trader based in India, we offer standard sizes but also cater to custom requirements to meet specific project needs.

FAQs of 410 Stainless Steel Perforated Sheets:

Q: How are 410 Stainless Steel Perforated Sheets manufactured?

A: These sheets are produced using advanced machinery that punches uniform holes into high-grade 410 stainless steel. After perforation, the sheets undergo powder coating for enhanced surface protection and aesthetics.Q: What industrial uses do these perforated sheets serve?

A: The 410 Stainless Steel Perforated Sheets are commonly used for filtration, ventilation, screening, and decoration in industries such as chemical processing, food production, and construction.Q: When should I choose powder-coated perforated sheets over non-coated ones?

A: Powder-coated sheets are preferable when increased resistance to corrosion, abrasion, or harsh environmental conditions is required. The coating extends the products lifespan and maintains its silver finish.Q: Where are these perforated sheets supplied from in India?

A: We operate as an exporter, manufacturer, supplier, and trader based in India, offering prompt deliveries nationwide and to international clients from our specialized facilities.Q: What benefits do 410 stainless steel perforated sheets offer to industrial users?

A: Users benefit from exceptional strength, corrosion resistance, and consistent quality. The powder coating further enhances durability, making these sheets cost-effective for long-term industrial use.Q: How can these sheets be customized for specific projects?

A: While standard sizes are available, we accommodate custom requests regarding perforation patterns, dimensions, and surface finishes to suit unique project requirements.Q: What is the process for ordering these sheets as an overseas client?

A: International clients can place orders directly through our export division. We ensure compliance with shipping protocols and provide support throughout the order, production, and delivery process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Perforated Sheet Category

430 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , 430 Stainless Steel

Surface Treatment : Other , Polished, Matte, or as required

Application : Filtration, Ventilation, Screening, Decoration, Machinery, Food Industry

Feature : Corrosion resistance, Durability, Uniform perforation, Good weldability

330 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , 330 Stainless Steel

Surface Treatment : Other , Polished, Matt Finish

Application : Industrial, Chemical Processing, Oil & Gas, Furnace Parts, Heat Exchangers, Architectural, Food Processing

Feature : Corrosion Resistant, Durable, High Strength, Heat Resistant

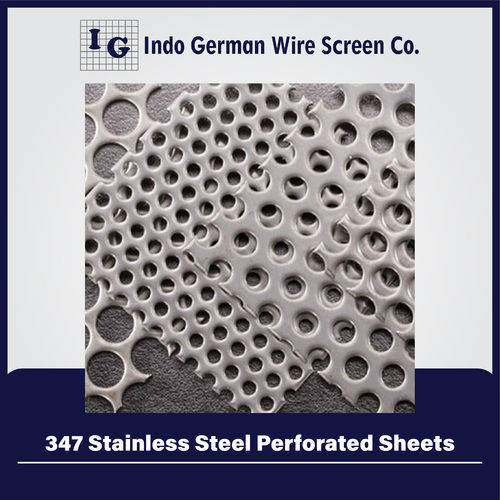

347 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , 347 Stainless Steel

Surface Treatment : Other , Polished, Mill Finish

Application : Chemical Processing, Food Industry, Power Generation, Petrochemical, Heat Exchangers

Feature : Corrosion Resistant, High Temperature Strength, Excellent Weldability, Durability

321 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , 321 Stainless Steel

Surface Treatment : Other , Polished, Mill finish

Application : Architectural screens, Filters, Guards, Decorative panels, Industrial applications

Feature : Corrosion resistant, High strength, Superior finish, Excellent forming and welding characteristics

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry