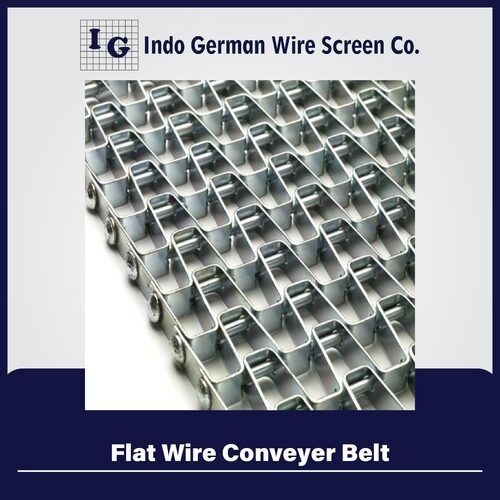

Flat Wire Conveyer Belt

Price 50 INR/ Unit

Flat Wire Conveyer Belt Specification

- Hole Shape

- Rectangular

- Wire Gauge

- 12 SWG

- Aperture

- 25 mm x 50 mm

- Length

- 2000 mm

- Surface Treatment

- Galvanized

- Product Type

- Flat Wire Conveyer Belt

- Mesh Type

- Open mesh

- Mesh Style

- Flat wire mesh

- Material

- Mild Steel

- Alloy

- Non-Alloy

- Application

- Conveying, Industrial Use, Food Processing, Packaging Lines

- Dimensions

- 400 mm width x 2000 mm length

- Wire Diameter

- 2 mm

- Weight

- 18 kg

- Color

- Silver Grey

About Flat Wire Conveyer Belt

Flat Wire Conveyor Beltis also known as Industrial Vibrating Screen, crusher screen, and Wire cloth.Wire Mesh Conveyor Beltsare widely applicable in different industries for their various applications and come in different sizes and dimensions as well as based on customized needs of our customers.Flat Wire Conveyor Beltsare made of maximum strength steel to withstand heavy loading and with the durability to give you longer wear life. OurConveyor Beltsare available in a range.The most important features of these belts are a flat surface, easily cleanable and easy to replace the parts which are damaged.It is usually made using 302 stainless steel. They further provide faster drainage of liquids, free air circulation and ease of cleaning.Customizable for Varied Applications

The flat wire conveyor belt supports a wide range of industries including food processing, packaging, and general industrial conveying. With features like customizable belt pitch, thickness, and width, each belt adheres to specific load capacity and speed requirements. Reinforced and anti-warped edges ensure both safety and stability, making them suitable for applications demanding precision and reliability.

Exceptional Durability and Resistance

Engineered to withstand rigorous environments, the flat wire conveyor belt is both corrosion and heat resistanthandling operating temperatures up to 800C (as per material specification). The standard galvanized finish protects the mild steel wire mesh against oxidation, ensuring extended service life in harsh industrial settings without compromising the smoothness required for efficient operations.

FAQs of Flat Wire Conveyer Belt:

Q: How do I determine the appropriate flat wire conveyor belt specifications for my application?

A: To select the correct specifications, consider your load requirements, operating temperature, and belt speed. The belt can be custom-designed with widths from 100 mm to 4000 mm, thicknesses between 2 mm and 6 mm, and specific pitch as needed. Providing details about your application ensures the belt matches your unique industrial or processing needs.Q: What materials are used for the flat wire conveyor belt and what are their benefits?

A: The belt is constructed primarily from mild steel, which is further treated with a galvanized finish for corrosion resistance. This material choice offers durability, high tensile strength, and suitability for a range of operating temperatures up to 800C, making it ideal for demanding environments like food processing and packaging.Q: Where can the flat wire conveyor belt be installed?

A: These conveyor belts are adaptable and can be installed in various settings such as industrial manufacturing plants, food processing facilities, and packaging lines. They are suitable for both lightweight and heavy-duty applications due to their reinforced edges and versatile design.Q: What is the process for installing and maintaining a flat wire conveyor belt?

A: Installation is straightforward due to the belts robust yet flexible structure. Simply align the belt on the conveyor frame, secure the welded or knuckled edges, and connect as specified. Regular inspections for tension and wear, along with basic cleaning, ensure longevity and efficient operation.Q: How does the reinforced edge benefit the operation of the conveyor belt?

A: Reinforced edges are designed to prevent warping and enhance safety by minimizing edge fraying or breakage. This feature ensures smooth tracking and handling, reducing downtime and maintenance costs, especially during high-speed or heavy-load conveying tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Types of Wire Mesh Conveyor Belt Category

Food grade Wire Mesh Conveyor Belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Metal Alloys

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

Wire Mesh Conveyer Belt with Baffle

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Stainless Steel (304/316), Mild Steel

Product Type : Other, Wire Mesh Conveyer Belt with Baffle

Color : Metallic Silver

Surface Treatment : Other, Galvanized/Polished

Custom Edge Conveyer Belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Product Type : Wire Mesh

Color : Black

Surface Treatment : Coated

Wicket Edge Wire Mesh Conveyor Belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry