Wire Mesh Conveyer Belt with Baffle

Price 50 INR/ Unit

Wire Mesh Conveyer Belt with Baffle Specification

- Surface Treatment

- Galvanized/Polished

- Aperture

- 6 mm to 25 mm

- Wire Gauge

- 10-16 SWG

- Length

- Customized as per requirement

- Hole Shape

- Rectangular

- Product Type

- Wire Mesh Conveyer Belt with Baffle

- Mesh Type

- Balanced Spiral Mesh

- Mesh Style

- Woven Mesh

- Material

- Stainless Steel (304/316), Mild Steel

- Alloy

- SS 304/316 or as specified

- Application

- Food Processing, Furnace, Baking, Drying, Cooling and Packaging Conveyors

- Dimensions

- Custom Dimensions

- Wire Diameter

- 1.6 mm - 5 mm

- Weight

- As per size and material

- Color

- Metallic Silver

- Temperature Resistance

- Up to 1200°C

- Maintenance

- Low maintenance, easy to replace and clean

- Load Capacity

- Medium to Heavy Duty

- Baffle Height

- 20 mm - 100 mm (customizable)

- Accessories

- Side Chains, Drive Chains, Flights, Sprockets

- Open Area Percentage

- Up to 80% depending on mesh size

- Pitch

- 12 mm - 40 mm

- Tensile Strength

- High tensile for industrial applications

- Conveyor Speed Compatibility

- Up to 30 m/min

- Edge Type

- Welded or Chain Linked

About Wire Mesh Conveyer Belt with Baffle

The Wire Mesh Conveyor Belt is manufactured using high-grade materials in accordance with industry standards. Wire Mesh Conveyor Belt provides a custom engineered solution for all heavy-duty applications for minerals, ores, aggregates, and more. Wire Mesh Conveyor Belt with Baffle are made for maximum strength steel to withstand heavy loading and with the durability to give you longer wear life. Our Conveyor Belts are available in a range of sizes from 8 x 4 (2.4 m x 1.2 m) to 8 x 24 (2.4 m x 7.3 m).

Stainless Steel Conveyor Belt With Baffle is most commonly used in industrial conveyors for material handling applications. It is made with flat wire spirals that are connected across the belt width with either straight or crimped cross bars. These belts with baffles are easy and convenient to use with high flexibility, good transparency and anti- temperature advantages.

Food grades Wire Mesh Conveyor Belts are available in different sizes and wide-range can be customized to fit your exact specifications in order to meet your specific application requirements. We offer an exclusive range of Wire Mesh Conveyor Belt with Baffles at unmatched quality and market leading prices.

High Temperature and Customizable Design

This wire mesh conveyor belt withstands extreme operational temperatures, making it suitable for both high-heat industrial applications and food industry tasks. With customizable features, including baffle height, mesh style, pitch, aperture, and length, it adapts seamlessly to specific process requirements. Its high tensile strength ensures reliability and longevity in demanding environments.

Low Maintenance and Easy Replacement

Built for convenience, this conveyor belt design emphasizes minimal maintenance requirements. Components like side chains, sprockets, and flights improve efficiency, while easy access enables swift replacement and cleaning, reducing downtime. The polished or galvanized finish enhances durability and simplifies everyday upkeep.

Versatility Across Industries

Designed to cater to a spectrum of applicationsfrom furnaces and food baking to drying and packagingthis belt operates efficiently at conveyor speeds up to 30 m/min. Its sturdy construction, customizable dimensions, and robust material choices (such as SS 304/316 or mild steel) accommodate various industrial, commercial, and export needs.

FAQs of Wire Mesh Conveyer Belt with Baffle:

Q: How can the baffle height and dimensions of the wire mesh conveyor belt be customized?

A: Baffle height can be specified between 20 mm and 100 mm, while the overall belt dimensions, including length and width, are customized during the ordering process to fit the specific conveyor and processing requirements of your facility.Q: What are the key benefits of using a wire mesh conveyor belt with high-temperature resistance?

A: This conveyor belt can withstand temperatures of up to 1200C, making it ideal for processes such as furnaces, baking, and industrial drying. Its durable construction ensures reliability and performance under prolonged heat exposure.Q: Where is this wire mesh conveyor belt commonly used?

A: It finds applications in food processing, furnace operations, drying and cooling lines, baking units, and packaging conveyors. Its customizable and robust design makes it versatile for a range of industries.Q: What materials are available for the construction of the conveyor belt?

A: Material options include stainless steel (grades 304 or 316), mild steel, or custom alloys as specified. These materials are chosen for their durability, corrosion resistance, and suitability in demanding industrial environments.Q: How easy is it to clean or maintain the wire mesh conveyor belt?

A: The belt is designed for low maintenance, featuring an open mesh design that facilitates easy cleaning. Components are accessible and simple to replace, which reduces operational downtime.Q: What process features support compatibility with various conveyor systems?

A: With options for edge type (welded or chain linked) and accessories like side chains, drive chains, flights, and sprockets, the belt can be integrated into different conveyor setups, supporting speeds up to 30 m/min and loading requirements from medium to heavy duty.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Types of Wire Mesh Conveyor Belt Category

Food grade Wire Mesh Conveyor Belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Metal Alloys

Product Type : Wire Mesh

Mesh Style : Plain Mesh

Surface Treatment : Coated

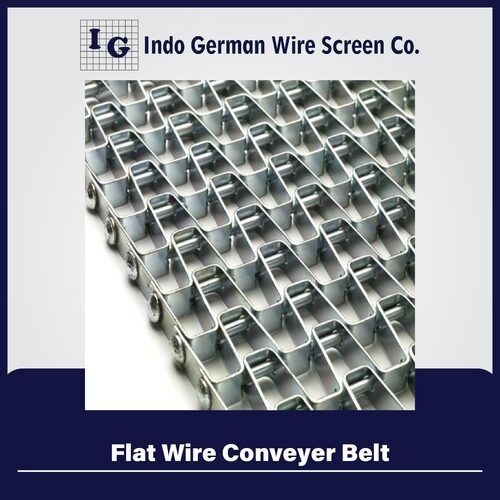

Flat Wire Conveyer Belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel

Product Type : Other, Flat Wire Conveyer Belt

Mesh Style : Other , Flat wire mesh

Surface Treatment : Galvanized

Custom Edge Conveyer Belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Product Type : Wire Mesh

Mesh Style : Plain Mesh

Surface Treatment : Coated

Wicket Edge Wire Mesh Conveyor Belt

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Product Type : Wire Mesh

Mesh Style : Plain Mesh

Surface Treatment : Coated

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry