Hastelloy Plain Weave Wire Mesh

Price 50 INR/ Unit

MOQ : 1 Unit

Hastelloy Plain Weave Wire Mesh Specification

- Aperture

- 0.025 mm to 10 mm

- Wire Gauge

- 10 SWG to 36 SWG

- Hole Shape

- Square

- Surface Treatment

- Polished / Uncoated

- Length

- 1 m, 15 m, 30 m or as required

- Product Type

- Plain Weave Wire Mesh

- Mesh Type

- Woven Wire Mesh

- Mesh Style

- Plain Weave

- Material

- Hastelloy (mainly C-276, C-22, C-2000, B-2 grades)

- Alloy

- Nickel-Molybdenum-Chromium (example: Hastelloy C-276, C-22, B-2 types)

- Application

- Filtration, Oil & Gas, Chemical Processing, Petrochemicals, Aerospace, Marine, Environmental, Food Processing

- Dimensions

- Width up to 2 m, custom sizes available

- Wire Diameter

- 0.025 mm to 3 mm

- Weight

- Varies as per mesh and size

- Color

- Metallic Silver

- Temperature Range

- Withstands up to 1000°C

- Packing

- Rolls, Wooden Cases, or as required

- Corrosion Resistance

- Excellent against acids, chlorides, and seawater

- Minimum Order Quantity

- 1 Roll

- Thickness

- As per wire diameter & mesh configuration

- Porosity

- Controlled, application-specific

- Weave Type

- Plain Weave

- Open Area

- 6% to 85% depending on mesh size

- Roll Length

- Standard 15 m, customizable

- Manufacturing Method

- Precision weaving

- Edge Type

- Plain cut or selvage edge

About Hastelloy Plain Weave Wire Mesh

We have become a major supplier of these products into an extensive range of markets and applications across India and the globe. Our clients select our range of products for their economical prices, dimensional preciseness, and high-durability. At Indo German Wire Screen Co., we are the professional people delivering high-quality and superior-performance products that have been appreciated by all of our previous customers.Superior Corrosion and Temperature Performance

Hastelloy Plain Weave Wire Mesh stands out for its remarkable resistance to harsh chemicals, acids, and seawater, which is ideal for chemical processing, marine, and oil & gas operations. Its ability to tolerate temperatures up to 1000C ensures consistent functionality in extreme environments, delivering longevity and reliability.

Customizable Solutions for Diverse Applications

Available in multiple wire gauges, mesh sizes, and roll lengths, this wire mesh adapts to filtration, separation, and screening requirements in various sectors. Custom dimensions, aperture sizes, and packing methods accommodate unique project specifications, while options for plain cut or selvage edges optimize strength and performance.

FAQs of Hastelloy Plain Weave Wire Mesh:

Q: How is Hastelloy Plain Weave Wire Mesh manufactured?

A: Hastelloy Plain Weave Wire Mesh is produced using a precision weaving process. High-grade Hastelloy wires are woven together to create a uniform plain weave mesh, ensuring controlled porosity and excellent mechanical strength.Q: What are the benefits of using Hastelloy Plain Weave Wire Mesh in corrosive environments?

A: Its composition provides exceptional resistance to acids, chlorides, and seawater, minimizing the risk of corrosion, even in highly aggressive chemical or marine conditions. This enhances durability, reduces maintenance costs, and extends the service life of filters and screens.Q: When should I choose Hastelloy mesh over standard stainless steel options?

A: Select Hastelloy mesh when your application demands resistance to extreme acids, chlorides, or temperatures up to 1000C. Its especially advantageous in chemical processing, oil & gas, and marine environments where stainless steel may degrade.Q: Where can Hastelloy Plain Weave Wire Mesh be used?

A: Its widely applied in filtration systems, oil & gas refineries, chemical plants, aerospace components, food processing, environmental protection, and marine equipment due to its robust corrosion and heat resistance properties.Q: How can I customize the mesh size and roll dimensions?

A: Mesh size, wire gauge, roll length (from 1m to 30m), and width (up to 2m) can be specified according to project requirements. Custom apertures, edge types, and packaging options are also available for tailored solutions.Q: What is the process for ordering Hastelloy mesh, and what is the minimum order quantity?

A: You can place an order specifying your required mesh size, dimensions, and alloy grade. The minimum order quantity is just one roll, supporting both large-scale and small-scale projects.Q: What surface treatments and finishes are available for Hastelloy Plain Weave Wire Mesh?

A: The mesh is typically available in a polished or uncoated metallic silver finish, enhancing its visual appeal and corrosion resistance without compromising the materials inherent strength.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Plain Weave Wire Mesh Category

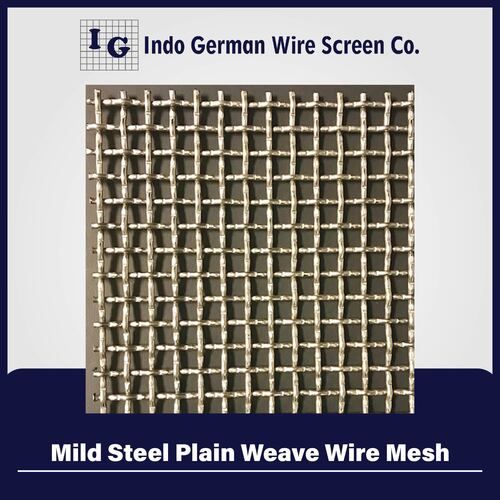

Mild Steel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel

Application : Other

Surface Treatment : Coated

Mesh Style : Plain Mesh

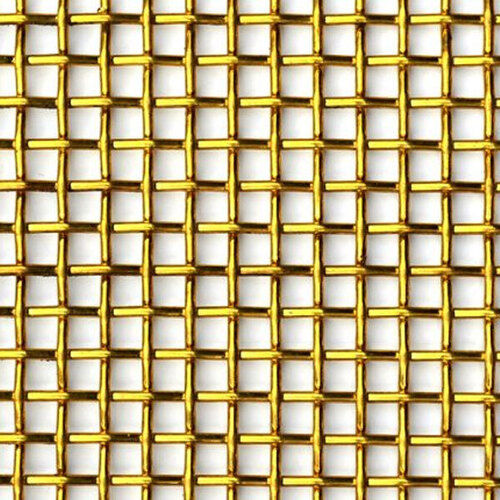

Brass Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Brass

Application : Other

Surface Treatment : Coated

Mesh Style : Plain Mesh

Nichrome A Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Nichrome

Application : Other

Surface Treatment : Coated

Mesh Style : Plain Mesh

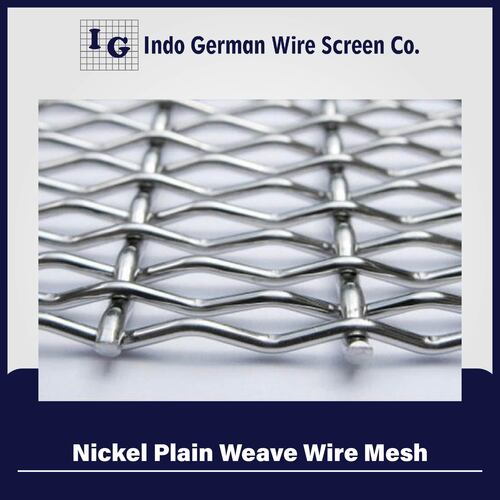

Nickel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other

Application : Other

Surface Treatment : Coated

Mesh Style : Plain Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry