Lead Free Sifter Sieves

Price 1000 INR/ Foot

Lead Free Sifter Sieves Specification

- Usage

- industrial

- Material

- Stainless Steel

- Size

- 20, 30, 40, 48 inch

- Product Type

- Lead Free Sifter Sieves

- Color

- Steel

Lead Free Sifter Sieves Trade Information

- Minimum Order Quantity

- 50 Feet, ,

- Payment Terms

- Paypal, Letter of Credit (L/C), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Domestic Market

- All India

About Lead Free Sifter Sieves

The reinforcing frame is designed to give complete support to the screen without reducing the output. The screen is passivized & micro polished to give a smooth filtration and separation. These Lead-Free Sifter Sieves are manufactured using high-grade material that makes these sieves resistant to corrosion and abrasion. Lead Free Sifter sieves have a glossy look and are dimensionally accurate.

Product details

|

Diameter |

20, 30, 40, 48 inch |

|

Material Grade |

SS 304, 316 |

|

Mesh |

4- 400 |

|

Type |

Cross Welded to bottom of ring |

|

Size/Dimension |

30 demister 20 demister 12 demister 48 demister 36 dia |

High-Quality Stainless Steel Construction

Our sifter sieves are manufactured using premium stainless steel, contributing to corrosion resistance and ensuring no lead contamination during industrial processes. Each sieve is meticulously designed for long-term durability and optimal safety in separation and filtration operations, aligning with international quality standards.

Versatile Sizing for Varied Industrial Needs

The sieves are available in multiple diameter options20, 30, 40, and 48 inchesto accommodate diverse industrial requirements. Whether your operation needs fine separation or large batch processing, our sizing flexibility ensures you get the precise fit for your production line.

FAQs of Lead Free Sifter Sieves:

Q: How are lead free sifter sieves used in industrial applications?

A: Lead free sifter sieves made from stainless steel are used in industries for filtering, separating, or grading powders, granules, and liquids. They are crucial in processes where product purity and safety are essential, such as pharmaceutical, food, and chemical manufacturing.Q: What sizes are available for these stainless steel sifter sieves?

A: Our stainless steel sifter sieves are available in 20, 30, 40, and 48 inch diameters. This range allows industries to select the most suitable size according to their material volume and processing requirements.Q: When should industries choose lead free sifter sieves over standard options?

A: Industries should opt for lead free sifter sieves when they need to comply with stringent safety and health regulations, particularly in sectors like food and pharmaceuticals, where contamination prevention is critical for regulatory approval and consumer safety.Q: Where are these sieves manufactured and exported from?

A: These sieves are manufactured, supplied, and exported from India, meeting global standards for quality. As manufacturers and exporters, we supply to both domestic and international markets.Q: What is the process for ensuring the sieves remain lead free during manufacturing?

A: The lead free sifter sieves are produced using certified stainless steel, with careful quality checks at each stage to prevent lead contamination. The entire manufacturing process adheres to regulatory guidelines to guarantee product safety.Q: How does using stainless steel benefit industrial sifting operations?

A: Stainless steel offers advantages such as resistance to rust, easy cleaning, and impressive longevity, making it ideal for frequent use in harsh industrial environments. Its lead-free nature further ensures safe processing of sensitive materials.Q: What sectors most benefit from these sifter sieves?

A: Industries such as pharmaceuticals, food processing, chemicals, and agriculture significantly benefit from our lead free sifter sieves due to their hygienic structure and compliance with safety standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Perforated Sheet Category

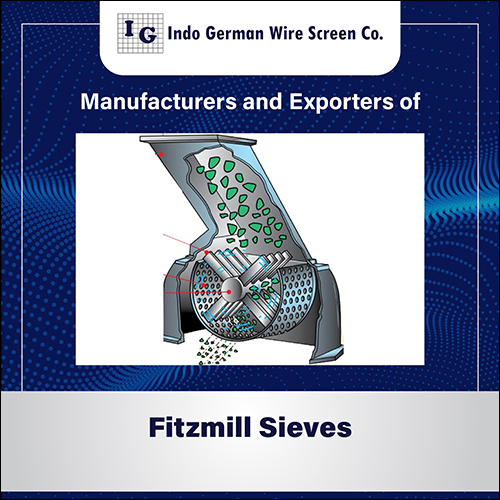

Fitzmill Sieves

Minimum Order Quantity : 10

Material : Stainless Steel

Product Type : Fitzmill Sieves

Shape : Round or Custom shapes

Thickness : 0.5 mm to 2 mm

Perforated Coils

Price Range 50.00 - 200.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Material : Stainless Steel Wire

Product Type : Perforated Coils

Shape : Round

Thickness : 1 15 Millimeter (mm)

Stainless Steel Perforated Sheet

Price Range 100.00 - 500.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Material : Stainless Steel

Product Type : Perforated Sheet

Shape : Rectangular

Thickness : 0.5 8.00 Millimeter (mm)

Aluminum Perforated Sheets

Price Range 25.00 - 150.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Material : Aluminum, Other

Product Type : Aluminum Perforated Sheets

Shape : Round

Thickness : 2, 3, 4, 5 Millimeter (mm)

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry