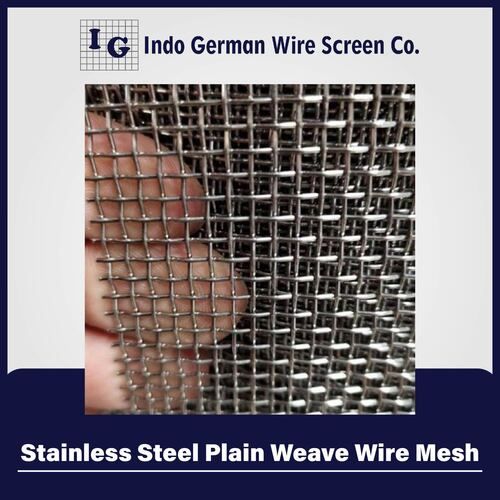

Stainless Steel Plain Weave Wire Mesh

Price 50 INR/ Unit

Stainless Steel Plain Weave Wire Mesh Specification

- Wire Gauge

- 24 Gauge

- Surface Treatment

- Coated

- Hole Shape

- Square

- Aperture

- 1 mm

- Length

- 30 Meter

- Product Type

- Wire Mesh

- Mesh Type

- Plain Weave

- Mesh Style

- Plain Mesh

- Material

- Stainless Steel

- Alloy

- SS 304

- Application

- Other

- Dimensions

- 1 Meter x 30 Meter

- Wire Diameter

- 0.5 mm

- Weight

- Approx. 5 kg/roll

- Color

- Gray

- Standard

- ASTM A580/A580M

- Feature

- Corrosion Resistant, Durable

- Roll Width

- 1 Meter

- Weave Type

- Plain Weave

- Temperature Resistance

- Up to 800°C

- Tensile Strength

- High

- Opening Size Tolerance

- ±0.03 mm

Stainless Steel Plain Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Stainless Steel Plain Weave Wire Mesh

Stainless Steel has these characteristics, in combination with usually low cost, greater sustainability, and superior aesthetic appearance, have led it becoming one of the most extensively used construction materials across a varied set of industries.Stainless Steel Plain Weave Wire Meshis extensively used for sieving, particle separation, filtering, safety and equipment protection, window screen, food processing industries, infill panels, and many more uses and find applications in wide range of industries according to mesh sizes andStainless Steel Plain Weave Wire Meshmaterials andare available with apertures from 10.7 mm (2 mesh) to 0.05 mm (325 mesh).

High-Quality Plain Weave Stainless Steel Mesh

Our plain weave wire mesh is crafted from SS 304 stainless steel, offering exceptional durability and resistance to corrosion. Its high tensile strength and tolerance to extreme temperatures make it suitable for environments demanding reliability and stability. Each roll measures 1 meter in width and 30 meters in length, making it practical for various installation requirements.

Precision Engineering and Standards Compliance

Manufactured to conform with ASTM A580/A580M standards, this mesh ensures uniform aperture size (1 mm) and strict opening size tolerance (0.03 mm). The 24-gauge, 0.5 mm wire diameter construction ensures mechanical robustness while maintaining flexibility for numerous uses.

Versatile Applications and Lasting Performance

Boasting a coated, corrosion-resistant gray surface, this wire mesh stands up to harsh chemicals and high heat (up to 800C). Its plain weave style and square holes enable use in filtration, separation, architectural facades, or protective barriers, providing lasting performance in both industrial and commercial settings.

FAQs of Stainless Steel Plain Weave Wire Mesh:

Q: How is the Stainless Steel Plain Weave Wire Mesh typically used?

A: This mesh is commonly used in filtration, sieving, separation processes, architectural projects, and barriers in industrial settings due to its durability, high tensile strength, and corrosion resistance.Q: What makes this mesh suitable for high-temperature applications?

A: Manufactured from SS 304 stainless steel with a coated finish, the mesh maintains strength and integrity at temperatures up to 800C, ensuring consistent performance in environments exposed to extreme heat.Q: When should I choose plain weave over other mesh types?

A: Plain weave is ideal when precise aperture control, structural consistency, and moderate strength are required. It is commonly selected for fine filtration, protective screens, and architectural detailing.Q: Where is this wire mesh commonly installed?

A: The mesh is widely used in industrial plants, food processing units, laboratories, construction sites, and architectural applications within India and internationally.Q: What is the process for manufacturing this stainless steel mesh?

A: The mesh is produced by weaving SS 304 wires in a plain weave pattern according to ASTM A580/A580M standards. After weaving, a protective coating is applied to enhance corrosion resistance and longevity.Q: How does the precise aperture and tolerance benefit industrial users?

A: The 1 mm aperture with a tight 0.03 mm tolerance ensures consistent, reliable filtration or separation performance, reducing the risk of material contamination and ensuring quality control.Q: What advantages does stainless steel offer over other mesh materials?

A: Stainless steel, particularly SS 304, provides superior resistance to corrosion, strength at high temperatures, and durability, resulting in lower maintenance and longer service life compared to alternative materials.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Weave Wire Mesh Category

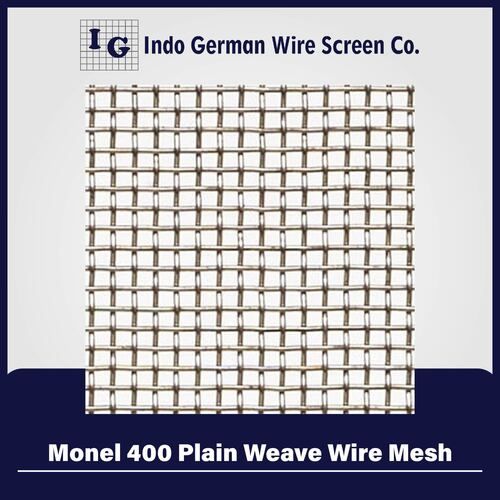

Monel 400 Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, As Required

Mesh Style : Plain Weave, Other

Application : Other, Industrial Screening Filtration Separation

Product Type : Wire Mesh

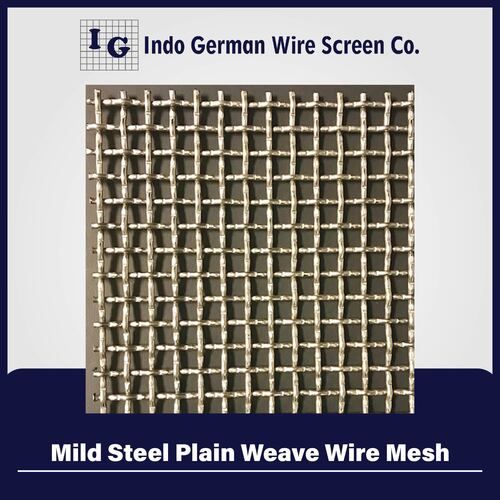

Mild Steel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Coated

Mesh Style : Plain Mesh

Application : Other

Product Type : Wire Mesh

Hastelloy Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, Polished / Uncoated

Mesh Style : Other , Plain Weave

Application : Other, Filtration, Oil & Gas, Chemical Processing, Petrochemicals, Aerospace, Marine, Environmental, Food Processing

Product Type : Other, Plain Weave Wire Mesh

Inconel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, Annealed / Bright

Mesh Style : Other , Plain Weave

Application : Other, Hightemperature filtration, Chemical processing, Aerospace, Heat Treatment

Product Type : Other, Plain Weave Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry