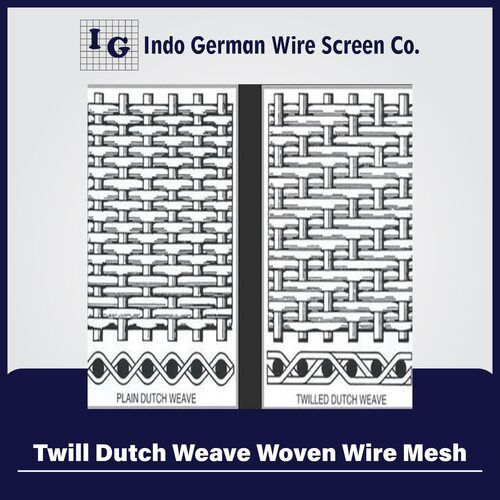

Twill Dutch Weave Woven Wire Mesh

Price 50 INR/ Unit

Twill Dutch Weave Woven Wire Mesh Specification

- Hole Shape

- Rectangular

- Surface Treatment

- Polished

- Wire Gauge

- 28 Gauge

- Aperture

- 0.1 mm

- Length

- 30 Meter (m)

- Product Type

- Woven Wire Mesh

- Mesh Type

- Industrial Mesh

- Mesh Style

- Woven Mesh

- Material

- Stainless Steel

- Alloy

- SS 304

- Application

- Filtration, Sifting, Sieving

- Dimensions

- Width 1 Meter

- Wire Diameter

- 0.2 mm

- Weight

- 8 kg per roll

- Color

- Silver

- Weave Type

- Twill Dutch Weave

- Edge Type

- Plain, Cut, or Selvage

- Mesh Count (Warp x Weft)

- 325 x 2300

- Manufacturing Method

- Precision Woven

- Tensile Strength

- High

- Packing Type

- Rolls, Wrapped in Waterproof Paper and Wooden Case

- Temperature Resistance

- Up to 600°C

- Usage

- Chemical, Pharmaceuticals, Aerospace, Petroleum Industry

- Corrosion Resistance

- Excellent

About Twill Dutch Weave Woven Wire Mesh

Twill Dutch Weave Woven Wire Mesh is technically wire mesh panel accurately manufactured by woven to size in the same technique cloth is woven manufactured on a loom. Twill Dutch Woven Wire Mesh is the combination of dutch Woven Wire Mesh and twill Woven Wire Mesh in which the weft wires passes alternately over and under two warp wire forming a finer mesh in the warp direction and the warp wires forms a coarser mesh in the warp direction in the same weaving. Twill Dutch Weave Mesh is produced with the weft wires packed together in the same principle as Plain Dutch Weave but with double the number of weft wires woven in an over two, under two pattern. The weft wires overlie each other creating a sinuous path of filtration making the cloth robust with a smooth surface and the finer weft wires and micro pore sizes provide outstanding flow characteristics.High Performance Filtration Solutions

Engineered for efficiency, the Twill Dutch Weave Woven Wire Mesh is perfect for demanding filtration, sifting, and sieving processes in various industrial settings. Its unique weave pattern and high mesh count ensure precise particle retention, while robust SS 304 stainless steel construction maintains structural integrity and extends service life even under high temperature and corrosive conditions.

Versatility and Robust Build

Withstanding temperatures up to 600C and offering remarkable corrosion resistance, this mesh is suitable for chemical, pharmaceutical, aerospace, and petroleum industries. Users can select from plain, cut, or selvage edge types, and the mesh is delivered in safe, waterproof packaging, ensuring that it arrives in pristine condition, ready for immediate use.

FAQs of Twill Dutch Weave Woven Wire Mesh:

Q: How is the Twill Dutch Weave Woven Wire Mesh manufactured?

A: This mesh is produced using precision weaving methods with SS 304 stainless steel wires, creating a dense, robust structure with a 325 x 2300 mesh count and a 0.1 mm aperture for high-performance filtration.Q: What makes this wire mesh suitable for high-temperature and corrosive environments?

A: Its construction from SS 304 stainless steel ensures excellent corrosion resistance and the ability to withstand temperatures up to 600C, making it highly reliable in harsh and industrial settings.Q: When should I choose a Twill Dutch Weave over other mesh types?

A: Opt for this weave when extremely fine filtration or separation is required, especially when managing high mechanical stress or corrosive substances, such as in chemical, pharmaceutical, or petroleum industries.Q: Where can this woven mesh be used effectively?

A: It is widely applicable in filtration, sifting, and sieving within industrial sectors like pharmaceuticals, chemicals, aerospace, and petroleum, where precision and durability are essential.Q: What is the benefit of the rectangular aperture and polished surface treatment?

A: The rectangular aperture enables accurate particle retention, and the polished surface minimizes material adhesion and contamination, ensuring efficient and hygienic processing.Q: How is the mesh supplied for export and industrial use?

A: Each roll is 30 meters in length, with a width of 1 meter and weighs 8 kg. Rolls are wrapped in waterproof paper and secured in wooden cases to ensure safe international transport.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Woven Wire Mesh types Category

Five Shed Twill Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Hole Shape : Other , Rectangular

Material : Metal Alloys

Surface Treatment : Coated

Application : Other

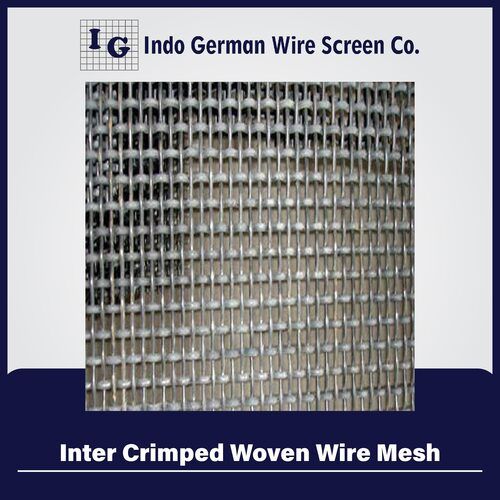

Inter Crimped Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Hole Shape : Other , Square or Rectangular

Material : Metal Alloys

Surface Treatment : Coated

Application : Other

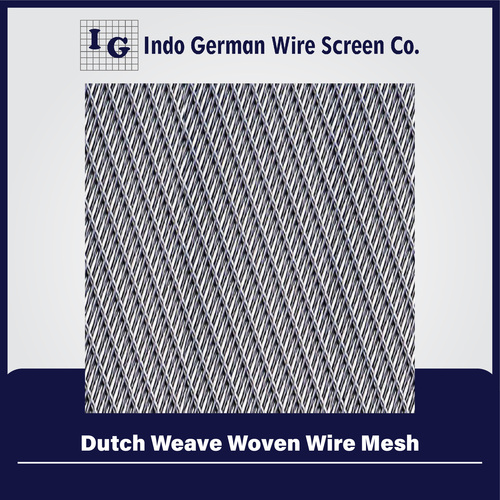

Dutch Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Hole Shape : Other , Rectangular

Material : Other, Stainless Steel, Brass, Copper

Surface Treatment : Other, Galvanized / Plain / Stainless Steel Finish

Application : Other, Filtration, Sieving, Industrial, Chemical Processing

Reverse Dutch Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Hole Shape : Other , Slotted

Material : Other, Stainless Steel (SS304, SS316), Mild Steel, Brass

Surface Treatment : Other, Galvanized, Polished, or Plain

Application : Other, Filtration, Sieving, Extruder screens, Chemical and Food industry

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry