Dutch Weave Woven Wire Mesh

Price 50 INR/ Unit

Dutch Weave Woven Wire Mesh Specification

- Aperture

- 0.025 mm 2 mm

- Surface Treatment

- Galvanized / Plain / Stainless Steel Finish

- Wire Gauge

- 16-36 SWG

- Length

- 15 m / 30 m

- Hole Shape

- Rectangular

- Product Type

- Woven Wire Mesh

- Mesh Type

- Woven Mesh

- Mesh Style

- Dutch Weave

- Material

- Stainless Steel, Brass, Copper

- Alloy

- SS 304, SS 316

- Application

- Filtration, Sieving, Industrial, Chemical Processing

- Dimensions

- Customized (common width: 1 m / 1.22 m / 1.5 m)

- Wire Diameter

- 0.017 mm 0.45 mm

- Weight

- Depends on specification

- Color

- Silver

- MOQ

- 10 Rolls

- Chemical Resistance

- Excellent (SS Mesh)

- Edge Finish

- Cut Edge / Selvage Edge

- Standard Roll Length

- 15 m, 30 m

- Opening

- Micron size openings for fine filtration

- Standard Roll Width

- 1 m, 1.22 m, 1.5 m

- Temperature Resistance

- Up to 800°C (for SS Mesh)

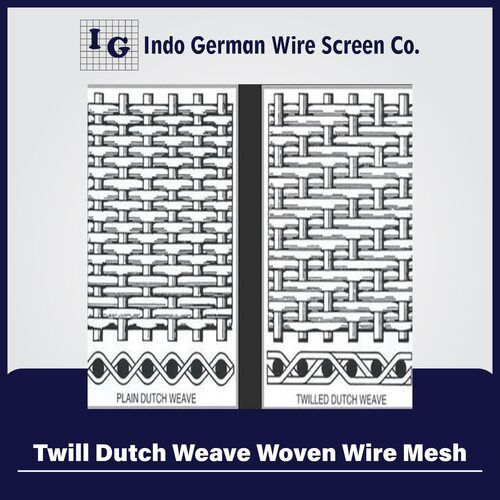

- Weave Type

- Plain Dutch Weave / Twill Dutch Weave

- Packing

- Packed in rolls with moisture-proof paper and plastic film

About Dutch Weave Woven Wire Mesh

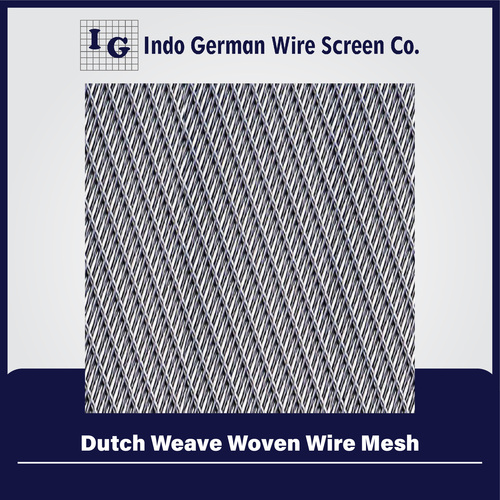

Dutch Weave Woven Wire Mesh is technically wire mesh panel accurately manufactured by woven to size in the same technique cloth is woven manufactured on a loom. Dutch Woven Wire Mesh or wire netting is a type of weave with larger warp wires than the weft wires. In Dutch wire cloth, the main feature is the warp and weft wire diameter thereby forming a firm and strong cloth producing a cloth with no readily visible apertures. The greater contrast density improves net thickness and filtering accuracy and the mesh will have greater life and will have a more significant increase than the average square mesh. The loom termsheddles, reeds, and bobbinare the same. Because the pre-straightened wires are welded at the intersections, relatively thinner diameter wires can be used over larger spaces. The mesh itself will remain strong and stable with a high percentage of open area.Comprehensive Filtration Solution

Designed for industrial and chemical processing, Dutch Weave Woven Wire Mesh delivers exceptional filtration efficiency. The precision weave stylesPlain and Twill Dutchcreate fine mesh openings suitable for separating even the smallest particles. Its robust stainless steel construction ensures durability and resistance to harsh operating conditions, making it an ideal choice for demanding environments.

Customization and Versatility

Clients can select from a broad spectrum of mesh openings, wire gauges, and roll dimensions to suit their application. Mesh edges can be supplied as cut or with a reinforced selvage for added strength. Additionally, multiple surface treatments are available, allowing further adaptation to chemical or environmental demands.

FAQs of Dutch Weave Woven Wire Mesh:

Q: How is Dutch Weave Woven Wire Mesh manufactured and what does the weave type signify?

A: Dutch Weave Woven Wire Mesh is produced by interlacing wires in a specific pattern: either Plain Dutch (simpler, tightly packed) or Twill Dutch (more robust with a diagonal pattern). These weave types determine the meshs strength and filtration capability, with Twill Dutch typically used for higher pressure and finer filtration.Q: What applications is this mesh ideal for and when should one choose it?

A: This mesh is primarily used in industrial filtration, sieving, and chemical processing where fine particle retention and durability are critical. It should be selected when precise filtration at micron levels is required or when materials need to withstand high temperatures and chemical exposure.Q: Where can Dutch Weave Woven Wire Mesh be installed and utilized?

A: The mesh can be used in a variety of settings, including filtration systems, fluidized beds, sieves, and filters in chemical plants, food processing, pharmaceuticals, and metallurgy. Its versatility makes it suitable for both liquid and gas filtration tasks.Q: What is the process for customizing mesh dimensions or properties?

A: Customers can specify dimensions such as width, length, opening size, wire diameter, and edge finish based on their operational needs. After consulting with our team, a tailored production run is carried out, ensuring exact specifications are met for each order.Q: How does temperature and chemical resistance benefit the user?

A: With stainless steel variants capable of withstanding temperatures up to 800C and exhibiting excellent chemical resistanceespecially in SS 304 and SS 316 alloysthe mesh can be reliably installed in aggressive or high-temperature environments without loss of performance or corrosion.Q: What are the packaging details and minimum order requirements?

A: Mesh rolls are securely packed with moisture-proof paper and plastic film to prevent damage during transit and storage. The minimum order quantity is 10 rolls, with standard roll lengths of 15 or 30 meters and widths up to 1.5 meters.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Woven Wire Mesh types Category

Flat Top Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Mesh Style : Woven Mesh

Product Type : Wire Mesh

Material : Metal Alloys

Double Crimped Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Mesh Style : Crimped Wire Mesh

Product Type : Wire Mesh

Material : Metal Alloys

Twill Dutch Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Filtration, Sifting, Sieving

Mesh Style : Woven Mesh

Product Type : Other, Woven Wire Mesh

Material : Stainless Steel

Reverse Dutch Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Filtration, Sieving, Extruder screens, Chemical and Food industry

Mesh Style : Woven Mesh

Product Type : Other, Reverse Dutch Weave Woven Wire Mesh

Material : Other, Stainless Steel (SS304, SS316), Mild Steel, Brass

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry