Reverse Dutch Weave Woven Wire Mesh

Price 50 INR/ Unit

Reverse Dutch Weave Woven Wire Mesh Specification

- Aperture

- Fine (varies based on specification)

- Hole Shape

- Slotted

- Length

- Up to 30 meters per roll or customized

- Surface Treatment

- Galvanized, Polished, or Plain

- Wire Gauge

- As per requirement (typically 30 to 100 SWG)

- Product Type

- Reverse Dutch Weave Woven Wire Mesh

- Mesh Type

- Reverse Dutch Weave

- Mesh Style

- Woven Mesh

- Material

- Stainless Steel (SS304, SS316), Mild Steel, Brass

- Alloy

- SS304, SS316

- Application

- Filtration, Sieving, Extruder screens, Chemical and Food industry

- Dimensions

- Custom sizes available (Standard width: 1 m, 1.2 m, 1.5 m)

- Wire Diameter

- 0.025 mm - 2 mm

- Weight

- Depends on dimensions and wire diameter

- Color

- Silver / Metallic

About Reverse Dutch Weave Woven Wire Mesh

Reverse Dutch Weave Woven Wire Mesh is technically a wire mesh panel accurately manufactured by woven to size in the same technique cloth is woven, manufactured on a loom. Reverse Dutch Woven Wire Mesh has more thin warp wires and fewer, but larger, weft wires as this structure provides a high degree of stability and optimal resistance to high pressure. Reverse Dutch Woven Wire Mesh is specially designed for filtering. The reverse dutch weave has a very high level of mechanical load and a high flow and porosity level. Reverse Dutch Woven Wire Mesh is manufactured with smaller warp wires that are more numerous than the weft wires. The loom termsheddles, reeds, and bobbinare the same. Because the pre-straightened wires are welded at the intersections, relatively thinner diameter wires can be used over larger spaces. The mesh itself will remain strong and stable with a high percentage of open area.We offer an exclusive range of Reverse Dutch Weave Woven Wire Mesh at unmatched quality and market leading prices.

Precision Filtration for Industrial Applications

Optimized for fine filtration, the Reverse Dutch Weave Woven Wire Mesh features a unique construction with thick warp and fine weft wires, delivering low porosity and high mechanical strength. Its versatility makes it a preferred choice for demanding processes in the chemical, food, and extrusion industries, ensuring reliable performance and extended mesh service life.

Robust Materials and Customizable Design

Whether your requirement is stainless steels superior corrosion resistance or a specific wire gauge and mesh count, this mesh can be tailored to your precise specifications. Options include surface treatments like galvanization or polishing, various edge finishes, and custom rolls or cut pieces to fit your workflow and filtration needs.

FAQs of Reverse Dutch Weave Woven Wire Mesh:

Q: How is Reverse Dutch Weave Woven Wire Mesh typically used in industries?

A: This mesh is widely employed for liquid-solid separation, gas filtration, and fine sieving, particularly in applications such as extruder screens and filtration units in the chemical and food sectors. Its fine filtration capacity ensures greater product purity and process efficiency.Q: What benefits does the Reverse Dutch Weave pattern provide for filtration?

A: The patterns combination of thick warp wires and fine weft wires produces low porosity and robust structure, making it highly effective for retaining fine particles under high-pressure conditions, thus ensuring precise and consistent filtration results.Q: When should I choose stainless steel materials for my mesh?

A: Stainless steel variants, such as SS304 and SS316, are recommended when excellent corrosion resistance is required, especially for use in chemically aggressive environments or where high-temperature operation up to 800C is necessary.Q: Where can Reverse Dutch Weave Woven Wire Mesh be installed?

A: This mesh is suitable for installation in filtration equipment, extruder screen assemblies, and sieving machines across industrial sites, particularly in chemical and food processing plants, as well as in environments demanding high pressure and fine particle retention.Q: What process options are available for mesh finishing and packing?

A: Customers can select from surface treatments such as galvanizing, polishing, or leaving the mesh plain. Packing formats include rolls or cut pieces, both securely wrapped in waterproof materials to preserve mesh quality during transport and storage.Q: How can I customize the dimensions and specifications of the mesh?

A: The mesh can be manufactured according to your requirements regarding thickness, wire diameter (0.025 mm to 2 mm), mesh count, length (up to 30 meters per roll), and width (standard 1 m, 1.2 m, 1.5 m), ensuring the perfect fit for your application.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Woven Wire Mesh types Category

Flat Top Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Mesh Style : Woven Mesh

Product Type : Wire Mesh

Hole Shape : Other , Rectangular / Square

Five Shed Twill Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Mesh Style : Woven Mesh

Product Type : Wire Cloth

Hole Shape : Other , Rectangular

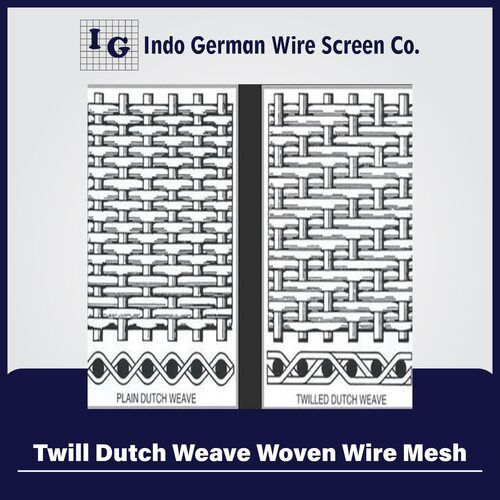

Twill Dutch Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Mesh Style : Woven Mesh

Product Type : Other, Woven Wire Mesh

Hole Shape : Other , Rectangular

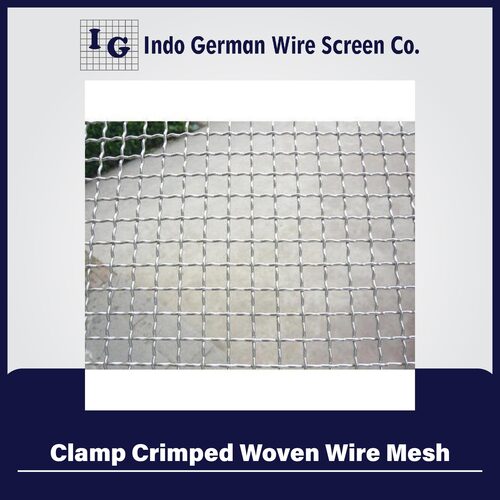

Clamp Crimped Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Mesh Style : Crimped Wire Mesh

Product Type : Wire Mesh

Hole Shape : Square Hole

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry