Stainless Steel Welded Plain Weave Wire Mesh

Price 50 INR/ Unit

Stainless Steel Welded Plain Weave Wire Mesh Specification

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Style

- Dutch Weave Wire Mesh

- Material

- Stainless Steel

- Application

- Other

- Color

- Gray

Stainless Steel Welded Plain Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Stainless Steel Welded Plain Weave Wire Mesh

Stainless Steel has these characteristics, in combination with usually low cost, greater sustainability, and superior aesthetic appearance, have led it becoming one of the most extensively used construction materials across a varied set of industries.

Warp wires and weft wires usually have the same diameter. Shute wire- Also known as weft wire that runs across mesh width. Warp wire- It runs in the direction of mesh length.Each weft wire goes alternatively over and under each warp wire, and vice versa.Stainless Steel Welded Plain Weave Wire Meshesare available with apertures from 10.7 mm (2 mesh) to 0.05 mm (325 mesh).

Innovative & Durable Wire Mesh Solutions

Discover our plain and Dutch weave wire mesh, crafted from premium stainless steel and enhanced with advanced coatings. Designed for durability and fine filtration, our mesh products meet diverse industrial needs. Sourced and supplied by a leading manufacturer and exporter in India, these meshes ensure longevity and resilience against corrosion, making them ideal for a wide variety of applications.

Wide Range of Industrial Applications

Our stainless steel wire mesh serves multiple sectors such as chemical processing, food industry, pharmaceuticals, and filtration systems. The welded and Dutch weave design offers excellent mechanical stability and precise control over particle separation, while the coated surface adds an extra layer of protection. Whether you require large-scale supply or custom specifications, we accommodate your exact requirements.

FAQs of Stainless Steel Welded Plain Weave Wire Mesh:

Q: How is Stainless Steel Welded Plain Weave Wire Mesh with a coated surface manufactured?

A: The wire mesh is produced by welding high-quality stainless steel wires together in a plain weave or Dutch weave pattern. After weaving and welding, the mesh undergoes a surface treatment process where a protective coating is applied, enhancing resistance to corrosion and wear.Q: What are the common applications of this wire mesh?

A: This mesh is extensively used in filtration systems, sieving and separation processes, industrial safety barriers, reinforcement in construction, and in various chemical and food processing industries due to its strength and precision.Q: When should I choose Dutch Weave Wire Mesh over other mesh styles?

A: Dutch weave wire mesh is preferable when you require fine filtration and better flow distribution. Its specific weave pattern is ideal for filtering very small particles while maintaining strength and rigidity.Q: Where do you source or supply this wire mesh from?

A: As an exporter, manufacturer, supplier, and trader based in India, we offer prompt delivery and customized solutions for both domestic and international clients, ensuring top-quality mesh products for various industries.Q: What is the process involved in applying the surface coating?

A: The mesh is thoroughly cleaned before coating to remove any impurities. A protective layer is then uniformly applied to the stainless steel surface using specialized techniques, which enhances its corrosion resistance and extends its service life.Q: How can this mesh be utilized in industrial environments?

A: It can be installed in filtration units, used as structural reinforcement, or applied in sieving and sorting equipment, benefiting from its strength, coated protection, and precision weave.Q: What benefits does the coated surface provide compared to uncoated mesh?

A: The coated surface significantly improves corrosion resistance and durability, especially in harsh or corrosive environments, reducing maintenance needs and extending operational lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Weave Wire Mesh Category

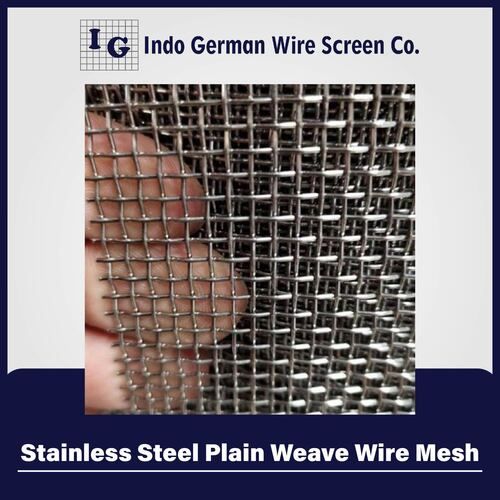

Stainless Steel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Color : Gray

Surface Treatment : Coated

Product Type : Wire Mesh

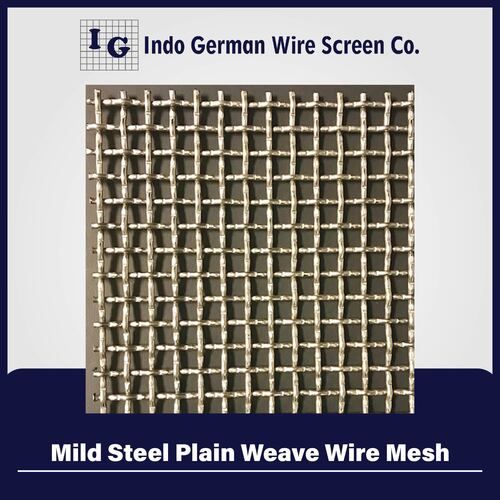

Mild Steel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel

Color : Gray

Surface Treatment : Coated

Product Type : Wire Mesh

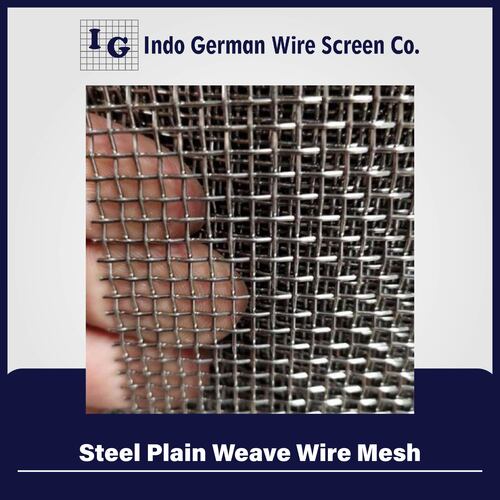

Steel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Color : Gray

Surface Treatment : Coated

Product Type : Wire Mesh

Nichrome A Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Nichrome

Color : Gray

Surface Treatment : Coated

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry