Tungsten Reverse Dutch Weave Wire Mesh

Price 50 INR/ Unit

Tungsten Reverse Dutch Weave Wire Mesh Specification

- Aperture

- 0.02-2.0 mm (as per specification)

- Hole Shape

- Rectangular (Reverse Dutch Weave pattern)

- Surface Treatment

- Cleaned; oxide-free finish

- Length

- 1-30 m (standard rolls or as requested)

- Wire Gauge

- customizable as per requirement (commonly 14-24 SWG)

- Product Type

- Industrial Wire Mesh (Reverse Dutch Weave)

- Mesh Type

- Woven Wire Mesh

- Mesh Style

- Reverse Dutch Weave

- Material

- High-Purity Tungsten

- Alloy

- 99.95% Tungsten

- Application

- Filtration, chemical processing, aerospace, lab research, high-temperature environments

- Dimensions

- Custom sizes, standard width 0.5-2 m

- Wire Diameter

- 0.025-2.0 mm

- Weight

- Variable based on mesh size and dimensions

- Color

- Silvery Grey (natural tungsten color)

- Mesh Count (warp/weft)

- Customizable (e.g., 12x64 mesh)

- Edge Type

- Plain or selvage edges

- Magnetic Properties

- Non-magnetic

- Delivery Form

- Rolls or cut-to-size sheets

- Tensile Strength

- High tensile and yield strength

- Standards

- ASTM B760, DIN 17850

- Operating Temperature

- up to 3380°C (melting point of tungsten)

- Packing

- Waterproof paper and wooden cases

- Corrosion Resistance

- Excellent against most acids and alkalis

- Standard Roll Width

- 1000 mm, 1220 mm (custom available)

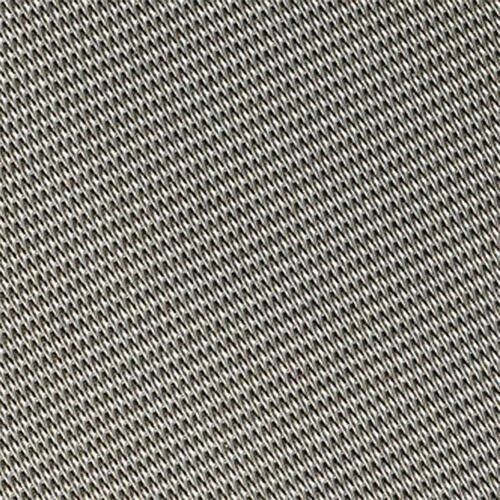

About Tungsten Reverse Dutch Weave Wire Mesh

Tungsten is an extremely hard metallic element that has an extremely high melting point and is corrosion resistant in many harsh environments. Tungsten is resistant to oxidation attack and corrosion in acidic and alkaline media and is used in elevated temperature filtration applications. Tungsten offers excellent high temperature mechanical characteristics and the smallest coefficient of thermal expansion among all metals.Superior Material and Construction

Manufactured from high-purity tungsten alloy (99.95%), this wire mesh is engineered for durability and resistance to extreme temperatures and corrosive chemicals. Its reverse Dutch weave pattern offers excellent filtration precision, with customizable mesh count and wire diameter to meet diverse requirements.

Versatile Applications

The mesh excels in filtration, chemical processing, aerospace, and scientific research where reliability, heat tolerance, and non-magnetic properties are critical. Custom dimensions and roll lengths allow integration into varied systems, leveraging its high tensile strength for high-demand industries.

Quality Assurance and Standards

Each mesh roll or sheet is produced under strict quality controls, adhering to ASTM B760 and DIN 17850 standards. Surface treatment ensures a cleaned, oxide-free finish, while packaging protects the product during shipment, reflecting the commitment to quality from an experienced exporter, manufacturer, and supplier in India.

FAQs of Tungsten Reverse Dutch Weave Wire Mesh:

Q: How is Tungsten Reverse Dutch Weave Wire Mesh typically utilized in industrial settings?

A: This wire mesh is predominantly used in filtration systems, chemical processing equipment, aerospace components, and laboratory apparatus. Its high temperature resistance, non-magnetic nature, and chemical stability make it suitable for applications requiring durability in challenging environments.Q: What customization options are available for mesh count, wire diameter, and dimensions?

A: Customers can specify mesh count (e.g., 12x64 mesh), wire diameter (0.0252.0 mm), and overall dimensions, including roll widths (1000 mm or 1220 mm) and lengths (standard 130 m or as requested). Edge types (plain or selvage) and hole shapes (rectangular, reverse Dutch weave pattern) are also customizable.Q: When should one choose tungsten wire mesh over other metallic meshes?

A: Tungsten mesh is ideal when operating environments involve extremely high temperatures (up to 3380C), aggressive chemicals, or require non-magnetic materials. It outperforms stainless steel, copper, and nickel meshes in scenarios demanding maximum heat and corrosion resistance.Q: Where is the wire mesh manufactured and supplied from?

A: This mesh is manufactured and exported by trusted companies in India, who are experienced providers and can supply worldwide through secure packaging in waterproof paper and wooden cases, ensuring product integrity on arrival.Q: What is the standard process for ordering and delivery of this wire mesh?

A: Customers specify their technical requirementsmesh count, wire gauge, dimensions, length, and edge preferences. The mesh is fabricated to these specifications, cleaned for an oxide-free finish, and delivered as rolls or cut-to-size sheets, packed suitably for transit, conforming to ASTM and DIN standards.Q: How does the reverse Dutch weave benefit filtration applications?

A: The reverse Dutch weave pattern ensures consistent and precise aperture size, enabling efficient separation of fine particles. Its unique weave design enhances mechanical strength, minimizes clogging, and supports high-pressure filtration tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reverse Dutch Weave Wire Mesh Category

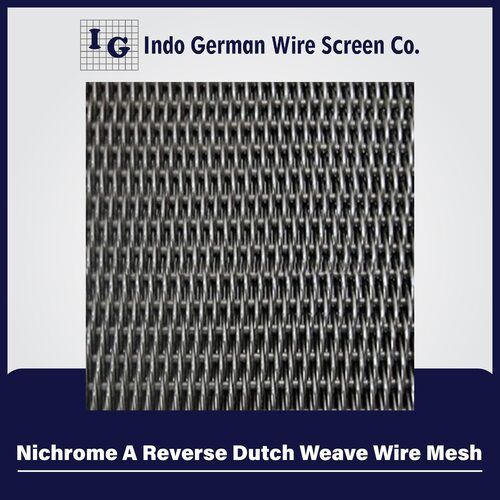

Nichrome A Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Plain Mesh

Product Type : Wire Mesh

Application : Other

Mesh Type : Other , Reverse Dutch Weave

Nickel Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Plain Mesh

Product Type : Wire Mesh

Application : Other, Filtration, Chemical Processing, Battery Electrode, Gas and Liquid Separation

Mesh Type : Other , Reverse Dutch Weave

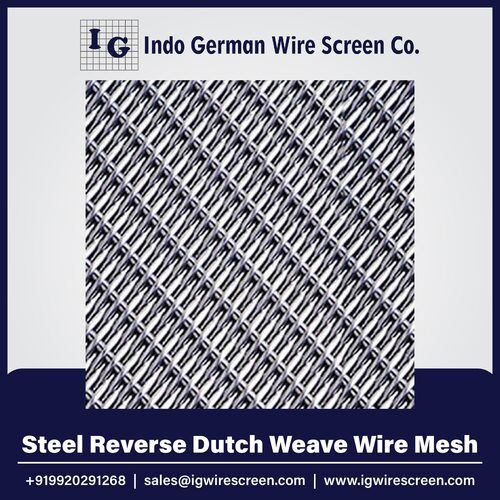

Steel Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Plain Mesh

Product Type : Wire Mesh

Application : Other

Mesh Type : Other , Reverse Dutch Weave

Iron Reverse Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Plain Mesh

Product Type : Wire Mesh

Application : Other

Mesh Type : Other , Reverse Dutch Weave

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry