Vibrating Screen for Refining

Price 50 INR/ Unit

Vibrating Screen for Refining Specification

- Wire Gauge

- 2 mm to 8 mm

- Length

- 1200 mm

- Hole Shape

- Rectangular

- Surface Treatment

- Polished

- Aperture

- 1 mm to 100 mm

- Product Type

- Vibrating Screen

- Mesh Type

- Vibrating / Sieving Mesh

- Mesh Style

- Woven Mesh

- Material

- Stainless Steel

- Alloy

- Grade 304/316 Stainless Steel

- Application

- Refining, Sieving, Grading, Filtering

- Dimensions

- 1200 mm x 1500 mm (customizable)

- Wire Diameter

- Varies as per design

- Weight

- Approx. 50 kg

- Color

- Silver

- Temperature Resistance

- Up to 300°C

- Number of Layers

- Single or Multi-Layer

- Frequency

- 50 Hz / 60 Hz

- Operating Voltage

- 220V / 380V / 415V

- Cleaning Method

- Manual / Automatic

- Mounting Type

- Floor Mounted / Customized

- Shape

- Rectangular Frame

- Usage Environment

- Industrial / Food Grade Applications

- Drive Type

- Electromagnetic Vibrator / Motor Driven

- Noise Level

- Low

- Capacity

- 1-10 TPH (depending on requirement)

- Screen Opening Size

- Customizable

- Corrosion Resistance

- Yes

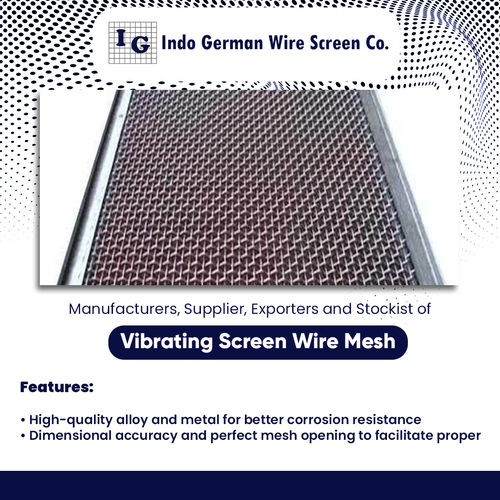

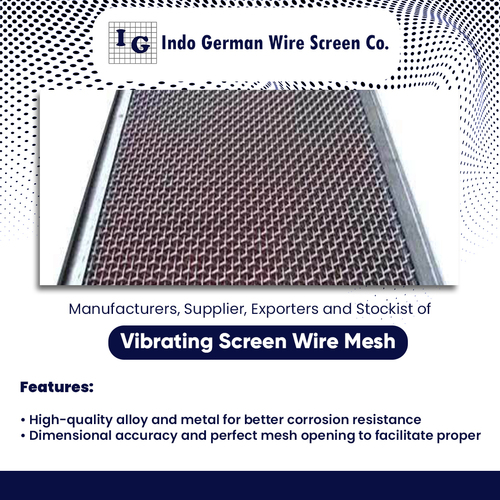

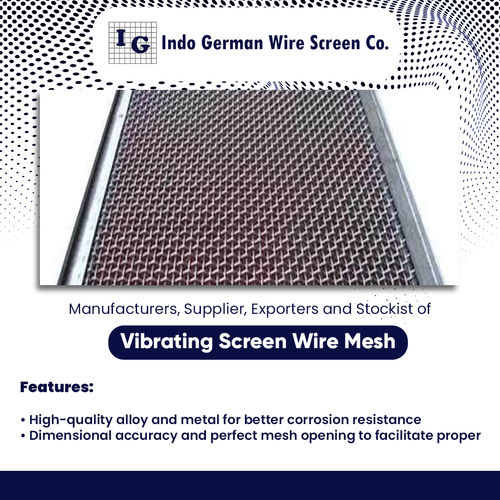

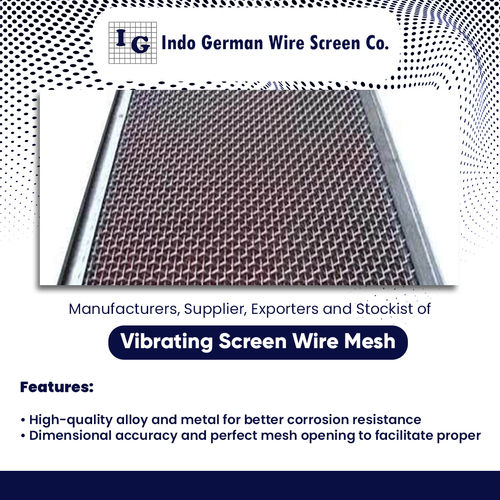

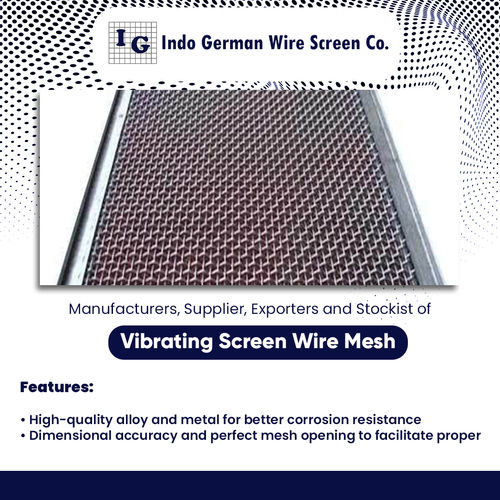

About Vibrating Screen for Refining

Vibrating Screensis also known as Industrial vibrating screen, wire cloth is extensively used for the refining process.TheVibrating Screensare manufactured using high-grade materials in accordance with industry standards.Vibrating Screensprovide a custom engineered solution for all heavy-duty applications for refineries and more.We offer an exclusive range ofVibrating Screen Wire Mesh for Refiningat unmatched quality and market leading prices.

Superior Design for Diverse Applications

Constructed with a durable rectangular frame and polished stainless steel, this vibrating screen supports demanding refining, grading, and sieving tasks. Custom mesh styles and opening sizes enable precise separation for both industrial and food applications. The floor or customized mounting options provide adaptability for different processing environments.

Advanced Performance and Easy Maintenance

Driven by either electromagnetic vibrators or motors, the unit delivers consistent operation at 50 Hz or 60 Hz and operates quietly. The corrosion-resistant alloys and temperature tolerance up to 300C guarantee reliability. Manual or automatic cleaning methods are available, ensuring convenient maintenance and uninterrupted performance.

FAQs of Vibrating Screen for Refining:

Q: How does the vibrating screen improve the refining process?

A: By utilizing precise mesh sizes and effective vibratory motion, the screen separates and grades materials efficiently, enhancing product purity and consistency in industrial and food-grade refining processes.Q: What are the customization options for screen openings and dimensions?

A: Screen opening size, hole shape, wire diameter, overall dimensions, and mesh style can be tailored to match specific processing requirements for various materials and throughput rates.Q: When should I use a single-layer versus a multi-layer vibrating screen?

A: Single-layer screens are best for straightforward separation, while multi-layer designs allow for simultaneous grading or filtering of different particle sizes, optimizing productivity for complex operations.Q: Where can this vibrating screen be installed and used?

A: It is suitable for installation in factories and plants handling industrial or food products. Floor mounting and customized setups enable integration into varied processing environments across India and globally.Q: What cleaning and maintenance methods are available?

A: The screen offers manual or automatic cleaning options, so users can select the most suitable method to reduce downtime and ensure hygiene according to operational needs.Q: How does corrosion resistance and temperature tolerance benefit users?

A: Grade 304/316 stainless steel construction and resistance to temperatures up to 300C provide longevity and reliability even in harsh processing conditions, minimizing maintenance and replacement costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibrating Screen Wire Mesh Category

Vibrating Screen Wire Mesh for Coal Industry

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Screening and grading coal in mining industry

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

Vibrating Screen Wire Mesh for Minerals

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

Vibrating Screen Wire Mesh for Cement Industry

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

Vibrating Screen Wire Mesh for Stone Crusher

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Stone Crusher, Mining, Screening, Quarrying

Product Type : Other, Vibrating Screen Wire Mesh for Stone Crusher

Color : Black / Silver / Custom

Surface Treatment : Other, Galvanized / Painted / Powder Coated

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry