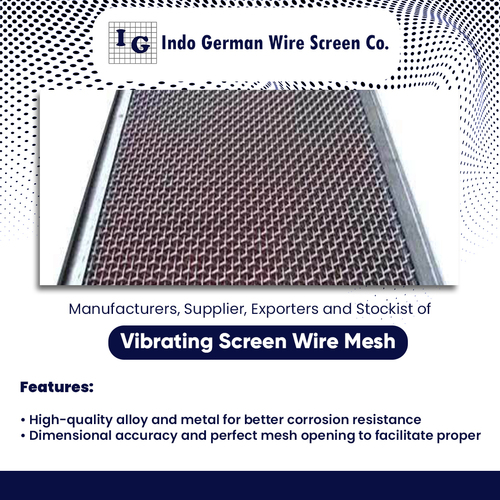

Vibrating Screen Wire Mesh for Stone Crusher

Price 50 INR/ Unit

Vibrating Screen Wire Mesh for Stone Crusher Specification

- Aperture

- 2 mm to 100 mm

- Surface Treatment

- Galvanized / Painted / Powder Coated

- Hole Shape

- Square / Rectangular

- Wire Gauge

- 2 mm to 16 mm

- Length

- Up to 30 meters

- Product Type

- Vibrating Screen Wire Mesh for Stone Crusher

- Mesh Type

- Crimped Mesh

- Mesh Style

- Woven Mesh

- Material

- High Carbon Steel / Stainless Steel

- Alloy

- Mild Steel / Stainless Steel

- Application

- Stone Crusher, Mining, Screening, Quarrying

- Dimensions

- Customized as per requirement

- Wire Diameter

- Up to 16 mm

- Weight

- Varies as per size and specification

- Color

- Black / Silver / Custom

- Corrosion Resistance

- Excellent with surface treatment

- Opening Size Tolerance

- ±0.5 mm

- Edge Finish

- Cut, Welded, or Hooked

- Usage

- Heavy Duty Screening

- Installation Method

- Bolted / Welded / Clamped

- Tensile Strength

- High - Industrial Grade

- Life Span

- High; Subject to usage conditions

- Operating Temperature

- -10°C to 200°C

- Packing Type

- Rolls or Sheets

About Vibrating Screen Wire Mesh for Stone Crusher

Vibrating Screensis also known as industrial vibrating screen, wire cloth, crusher screen forstone crusher applications.Vibrating screensproducts are widely applicable in different industries for their various applications and come in different sizes and dimensions as well as based on customized needs of our customers. TheVibrating Screensare manufactured using high-grade materials in accordance with industry standards.

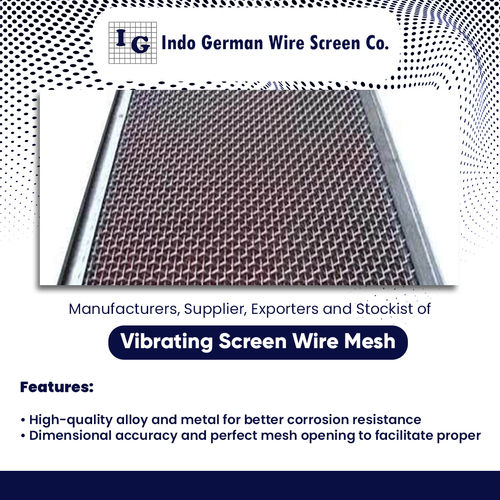

Our Vibrating Screens are available in all sizes

We offer an exclusive range ofVibrating Screen Wire Mesh for Stone Crusherat unmatched quality and market leading prices.

Engineered for Reliability

Our Vibrating Screen Wire Mesh is manufactured using premium high carbon or stainless steel, ensuring high tensile strength and industrial-grade durability. With advanced surface treatments like galvanizing, painting, or powder coating, each mesh promises prolonged life even under tough environmental conditions.

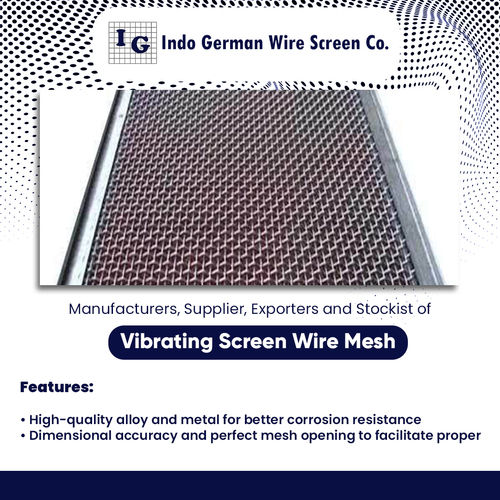

Versatile Installation and Customization

Designed for flexibility, our mesh can be installed using bolted, welded, or clamped methods, allowing adaptation to your specific machinery and site needs. Customization options are available for hole shapes, wire diameter, and length to match your screening application perfectly.

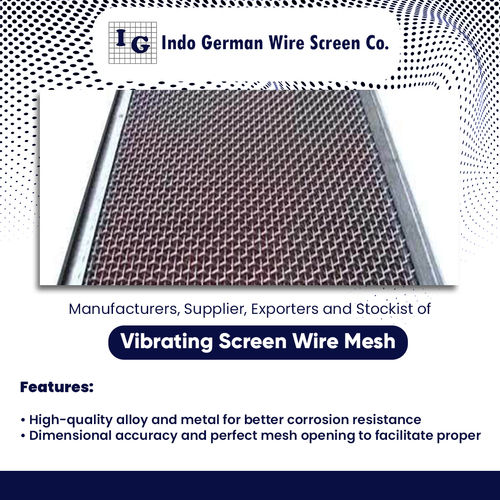

Adaptable Applications

Suited for heavy-duty screenings in stone crushers, mining operations, and quarrying, this mesh style is woven and crimped for reliable performance. Choose from a range of wire gauges, opening sizes, and edge finishes to fulfill your exact requirements with confidence in robust screen longevity.

FAQs of Vibrating Screen Wire Mesh for Stone Crusher:

Q: How is the Vibrating Screen Wire Mesh installed for stone crushing applications?

A: Installation can be performed using bolting, welding, or clamping methods. This ensures compatibility with various stone crusher machinery and makes the process efficient and stable depending on site requirements.Q: What wire diameters and aperture sizes are available for heavy-duty screening needs?

A: Wire Gauge options range from 2 mm to 16 mm, and aperture (opening) sizes span 2 mm to 100 mm. These can be customized to meet the specific demands of your screening application.Q: When should a particular edge finish like cut, welded, or hooked be chosen?

A: The edge finish should be selected based on operational needs and installation methods. Hooked edges offer secure fitting in vibrating screens, while cut or welded edges are suitable for bolting, welding, or clamping installations.Q: Where can these screening meshes be utilized apart from stone crushers?

A: Beyond stone crushing, these wire meshes are extensively used in mining, quarrying, and other heavy-duty screening processes, thanks to their resilience and adaptability to various materials and environments.Q: What process ensures excellent corrosion resistance in the wire mesh?

A: The mesh undergoes surface treatments such as galvanizing, painting, or powder coating. These processes form a protective barrier, shielding the mesh from moisture, chemicals, and abrasive conditions for sustained corrosion resistance.Q: How does the high tensile strength benefit screening operations?

A: Industrial-grade tensile strength allows the mesh to handle substantial mechanical stress and abrasive materials frequently encountered in screening. This ensures consistent performance and a longer lifespan.Q: What are the packing and customization options available for this product?

A: Vibrating Screen Wire Mesh is supplied in rolls or sheets, with length customizable up to 30 meters. Dimensions, color, hole shape, and surface treatment can be tailored to meet individual specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibrating Screen Wire Mesh Category

Vibrating Screen Wire Mesh for Minerals

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Other

Surface Treatment : Coated

Material : Metal Alloys

Color : Silver

Vibrating Screen for Separation

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Plain Mesh

Surface Treatment : Coated

Material : Metal Alloys

Color : Silver

Vibrating Screen Wire Mesh for Steel Industry

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Other

Surface Treatment : Coated

Material : Metal Alloys

Color : Silver

Vibrating Screen Wire Mesh for Sieving

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Other

Surface Treatment : Coated

Material : Metal Alloys

Color : Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry