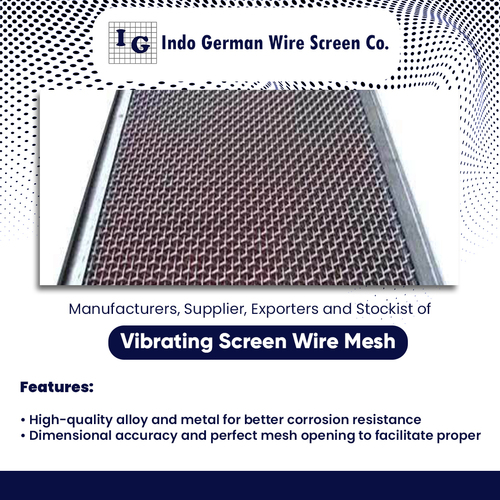

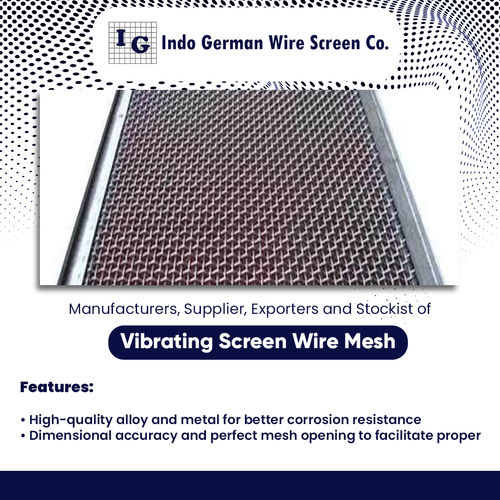

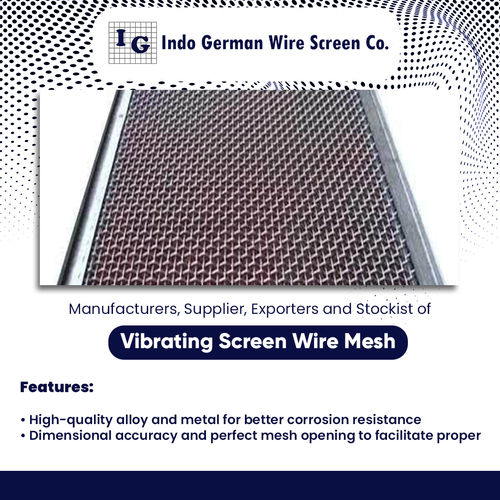

Vibrating Screen Wire Mesh for Coke Industry

Price 50 INR/ Unit

Vibrating Screen Wire Mesh for Coke Industry Specification

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Style

- Vibrating Screen Wire Mesh

- Material

- Metal Alloys

- Application

- Other

- Color

- Gray

Vibrating Screen Wire Mesh for Coke Industry Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Vibrating Screen Wire Mesh for Coke Industry

Vibrating Screensis also known as Industrial vibrating screen, wire cloth, crusher screen is extensively used in the Coke Industry.Vibrating screensproducts are widely applicable in different industries for their various applications and come in different sizes and dimensions as well as based on customized needs of our customers. TheVibrating Screensare manufactured using high-grade materials in accordance with industry standards.

Vibrating Screens aremade for durability to give you lengthier wear life and maximum strength steel to bear heavy loading. Our Vibrating Screens are available in a range of sizes from 8x 4 (2.4 m x 1.2 m) to 8 x 24(2.4 m x 7.3 m).

We offer an exclusive range ofVibrating Screen Wire Mesh for Coke Industryat unmatched quality and market leading prices.

Engineered for Endurance

Vibrating Screen Wire Mesh for the coke industry is engineered with high-quality metal alloys, ensuring resilience against tough processing demands. The advanced coating adds an extra layer of protection, preventing corrosion and wear. This results in longer service life and reliable operation, even under continuous usage.

Optimized Screening Efficiency

The meshs unique design allows for precise and efficient separation of materials, which is essential in coke production facilities. It minimizes blockages and ensures smooth operational flow, helping you maintain consistent product quality and reducing the need for frequent maintenance.

FAQs of Vibrating Screen Wire Mesh for Coke Industry:

Q: How is the Vibrating Screen Wire Mesh used in the coke industry?

A: The Vibrating Screen Wire Mesh is primarily used for separating and sizing coke particles. Its sturdy metal alloy construction and coated surface allow it to withstand the abrasive environment and repetitive vibrations typical in coke processing plants.Q: What materials are used in the construction of this wire mesh?

A: This wire mesh is constructed from selected metal alloys, renowned for their durability and resistance to wear. The entire mesh is further coated to enhance longevity and prevent corrosion, ensuring long-term performance in harsh industrial conditions.Q: When should the Vibrating Screen Wire Mesh be replaced?

A: Replacement is recommended when there is visible damage, deformation, or a decrease in screening efficiency. Regular inspections will help identify wear and tear caused by prolonged usage in the demanding environment of coke processing.Q: Where can this wire mesh be sourced from?

A: We are a manufacturer, exporter, supplier, and trader based in India, offering the Vibrating Screen Wire Mesh for domestic and international clients in the coke industry. Orders can be placed directly through our supply network.Q: What is the process involved in manufacturing this mesh?

A: The process involves selecting appropriate metal alloys, forming the mesh with precise apertures, applying a specialized coating for protection, and conducting rigorous quality checks to ensure each piece meets industry standards.Q: What are the key benefits of using coated Vibrating Screen Wire Mesh?

A: Coated Vibrating Screen Wire Mesh offers enhanced durability, resistance to corrosion, and reduced maintenance. Its design improves screening efficiency, making it a cost-effective choice for high-volume coke processing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibrating Screen Wire Mesh Category

Bee keeping Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Wire Diameter : 0.7 mm

Mesh Style : Plain Mesh

Application : Other

Surface Treatment : Coated

Vibrating Screen Wire Mesh for Minerals

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Wire Diameter : 0.8 mm to 5 mm

Mesh Style : Other

Application : Other

Surface Treatment : Coated

Vibrating Screen for Separation

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Wire Diameter : 1 mm 12 mm

Mesh Style : Plain Mesh

Application : Other

Surface Treatment : Coated

Vibrating Screen Wire Mesh for Cement Industry

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Wire Diameter : 1.5 mm to 3 mm

Mesh Style : Plain Mesh

Application : Other

Surface Treatment : Coated

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry