Double Crimped Woven Wire Mesh

Price 50 INR/ Unit

Double Crimped Woven Wire Mesh Specification

- Hole Shape

- Square

- Length

- 30 m (customizable)

- Wire Gauge

- 8-24 SWG

- Aperture

- 5 mm to 50 mm

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Double Crimped Woven

- Mesh Style

- Crimped Wire Mesh

- Material

- Metal Alloys

- Alloy

- Mild Steel, Stainless Steel (304/316), Galvanized Iron

- Application

- Other

- Dimensions

- Custom Sizes Available

- Wire Diameter

- 0.6 mm - 4 mm

- Weight

- Varies as per size and gauge

- Color

- Silver

- Finish

- Matt or Bright

- Tensile Strength

- High Tensile

- Packing

- Rolls or cut to length sheets

- Operating Temperature

- -40°C to 450°C (material dependent)

- MOQ

- 50 square meters (may vary)

- Corrosion Resistance

- Excellent (depending on material and coating)

- Weaving Type

- Double crimped (both warp and weft wires are crimped)

- Edge Type

- Plain, Clamped, or Welded Edge

- Usage

- Mining, Quarrying, Construction, Fencing, Industrial Filtration, Security

Double Crimped Woven Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Double Crimped Woven Wire Mesh

Superior Durability and Strength

Engineered with double crimped weaving technique, this wire mesh achieves impressive tensile strength, making it suitable for demanding industrial applications. The crimped formation adds stability and prevents wire movement, ensuring lasting performance even under heavy loads and frequent vibration.

Versatile Applications Across Industries

From mining and quarrying to fencing and industrial filtration, double crimped woven wire mesh is valued for its adaptability. Its customizable size, aperture, and material options make it an excellent solution for various sectors, including security, construction, and packaging.

FAQs of Double Crimped Woven Wire Mesh:

Q: How is the double crimped woven wire mesh manufactured?

A: The mesh is produced by crimping both warp and weft wires before weaving them together. This double crimping locks the wires securely in place, resulting in a rigid and durable mesh structure.Q: What materials and surface finishes are available for this mesh?

A: We manufacture double crimped woven wire mesh using mild steel, stainless steel (304/316), and galvanized iron. The mesh can have a matt or bright finish and may be supplied with various coatings depending on application requirements.Q: When should I use plain, clamped, or welded edge types?

A: Plain edges are ideal for general applications, welded edges offer added strength and security, while clamped edges are best for installations requiring easy fastening or additional stability at the perimeter.Q: Where is double crimped woven wire mesh commonly utilized?

A: This mesh is widely used in mining, quarrying, construction, fencing, industrial filtration, security installations, and packaging, thanks to its robustness and adaptable design.Q: What are the benefits of using high tensile, corrosion-resistant mesh?

A: High tensile strength ensures durability under stress, while excellent corrosion resistance provides longer service life, especially in harsh environments or where exposure to moisture or chemicals is common.Q: How can I order custom sizes and what is the minimum order quantity?

A: Custom dimensions, aperture, wire gauge, and lengths up to 30 meters are available to suit your requirements. The minimum order quantity is generally 50 square meters, but may vary based on your specific project needs.Q: What types of hole shapes and wire diameters are offered?

A: We provide meshes primarily with square or other customized hole shapes. Wire diameters range from 0.6 mm to 4 mm, allowing you to select the appropriate strength and filtration level for your application.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Woven Wire Mesh types Category

Flat Top Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Material : Metal Alloys

Mesh Style : Woven Mesh

Application : Other

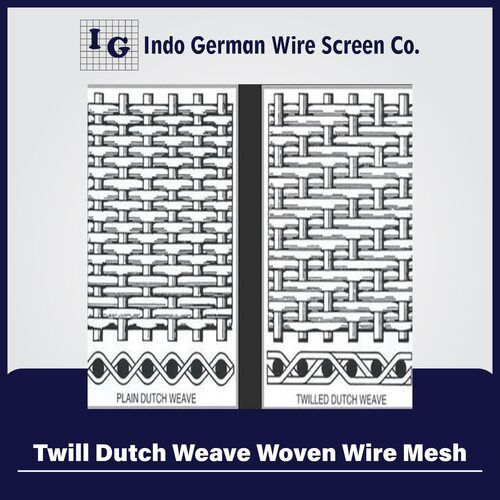

Twill Dutch Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Material : Stainless Steel

Mesh Style : Woven Mesh

Application : Other, Filtration, Sifting, Sieving

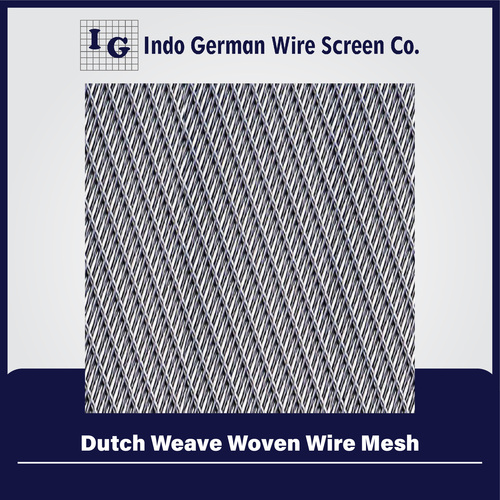

Dutch Weave Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Material : Other, Stainless Steel, Brass, Copper

Mesh Style : Other , Dutch Weave

Application : Other, Filtration, Sieving, Industrial, Chemical Processing

Pre Crimped Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Material : Metal Alloys

Mesh Style : Crimped Wire Mesh

Application : Other

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry